Titanium alloys are metals that contain a mixture of titanium and other chemical elements. Such alloys have very high tensile strength and toughness (even at extreme temperatures). They are light in weight, have extraordinary corrosion resistance and the ability to withstand extreme temperatures.

Titanium alloys are metals that contain a mixture of titanium and other chemical elements. Such alloys have very high tensile strength and toughness (even at extreme temperatures). They are light in weight, have extraordinary corrosion resistance and the ability to withstand extreme temperatures.

Types of Titanium Alloys

Titanium exists in two crystallographic forms. At room temperature, unalloyed (commercially pure) titanium has a hexagonal close-packed (hcp) crystal structure referred to as alpha (α) phase. When the temperature of pure titanium reaches 885 °C (called the β transus temperature of titanium), the crystal structure changes to a bcc structure known as beta (β) phase. Alloying elements either raise or lower the temperature for the α-to- β transformation, so alloying elements in titanium are classified as either α stabilizers or β stabilizers. For example, vanadium, niobium, and molybdenum decrease the α-to-β transformation temperature and promote the formation of the β phase.

- Alpha Alloys. Alpha alloys contain elements such as aluminum and tin and are preferred for high temperature applications because of their superior creep characteristics.. These α-stabilizing elements work by either inhibiting change in the phase transformation temperature or by causing it to increase. The absence of a ductile-to-brittle transition, a feature of β alloys, makes α alloys suitable for cryogenic applications. On the other hand, cannot be strengthened by heat treatment because alpha is the stable phase and thus they are not so strength as beta alloys.

- Beta Alloys. Beta alloys contain transition elements such as vanadium, niobium, and molybdenum, which tend to decrease the temperature of the α to β phase transition. Beta alloys have excellent hardenability, and respond readily to heat treatment. These materials are highly forgeable and exhibit high fracture toughnesses. For example, ultimate tensile strength of high-strength titanium alloy – TI-10V-2Fe-3Al is about 1200 MPa.

- Alpha + Beta Alloy. Alpha + beta alloys have compositions that support a mixture of α and β phases and may contain between 10 and 50% β phase at room temperature. The most common α + β alloy is Ti-6Al-4V. The strength of these alloys may be improved and controlled by heat treatment. Examples include: Ti-6Al-4V, Ti-6Al-4V-ELI, Ti-6Al-6V-2Sn, Ti-6Al-7Nb.

Grade 5 Titanium Alloy – Ti-6Al-4V

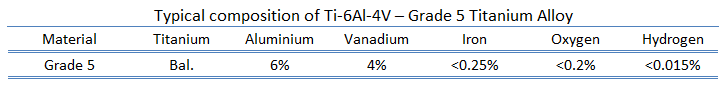

Grade 5 is the most commonly used alloy and it is an alpha + beta alloy. Grade 5 alloy accounts for 50% of total titanium usage the world over. It has a chemical composition of 6% aluminum, 4% vanadium, 0.25% (maximum) iron, 0.2% (maximum) oxygen, and the remainder titanium. Generally, Ti-6Al-4V is used in applications up to 400 degrees Celsius. It has a density of roughly 4420 kg/m3. It is significantly stronger than commercially pure titanium (grades 1-4) due to its possibility to be heat treated. This grade is an excellent combination of strength, corrosion resistance, weld and fabricability It is the prime choice for many fields of applications:

- Aircraft turbines

- Engine components

- Aircraft structural components

- Aerospace fasteners

- High-performance automatic parts

- Marine applications

We hope, this article, Composition of Grade 5 Titanium Alloy – Ti-6Al-4V, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.