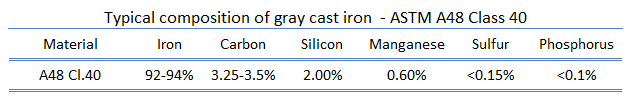

Gray cast iron is the oldest and most common type of iron in existence and probably what most people think of when they hear the term “cast iron”. The carbon and silicon contents of gray cast irons vary between 2.5 and 4.0 wt% and 1.0 and 3.0 wt%, respectively.

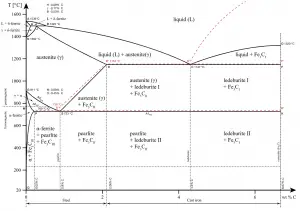

Gray cast iron is characterised by its graphitic microstructure, which causes fractures of the material to have a gray appearance. This is due to the presence of graphite in its composition. In gray cast iron the graphite forms as flakes, taking on a three dimensional geometry.

Gray cast iron has less tensile strength and shock resistance than steel, but its compressive strength is comparable to low- and medium-carbon steel. Gray cast iron has good thermal conductivity and specific heat capacity, therefore it is often used in cookware and brake rotors.

Gray cast iron have also an excellent damping capacity, which is given by the graphite because it absorbs the energy and converts it into heat. A large damping capacity is desirable for materials used in structures where unwanted vibrations are induced during operation such as machine tool bases or crankshafts. Materials like brass and steel have small damping capacities allowing vibration energy to be transmitted through them without attenuation.

We hope, this article, Composition of Gray Cast Iron, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.