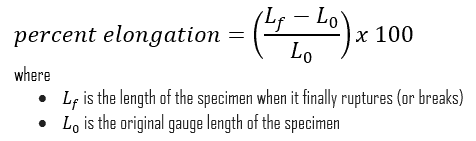

Ductility is more commonly defined as the ability of a material to deform easily upon the application of a tensile force, or as the ability of a material to withstand plastic deformation without rupture. Ductility is an important factor in allowing a structure to survive extreme loads, such as those due large pressure changes, earthquakes and hurricanes, without experiencing a sudden failure or collapse. It is defined as:

Ductility may also be thought of in terms of bendability and crushability. Usually, if two materials have the same strength and hardness, the one that has the higher ductility is more desirable. The ductility of many metals can change if conditions are altered. An increase in temperature will increase ductility. A decrease in temperature will cause a decrease in ductility and a change from ductile to brittle behavior. Ductile fracture (shear fracture) is better than brittle fracture, because there is slow propagation and an absorption of a large amount energy before fracture. Ductility is desirable in the high temperature and high pressure applications in reactor plants because of the added stresses on the metals. High ductility in these applications helps prevent brittle fracture. Ductility also contributes to another material property called toughness. Toughness combines strength and ductility in a single measurable property and requires a balance of strength and ductility.

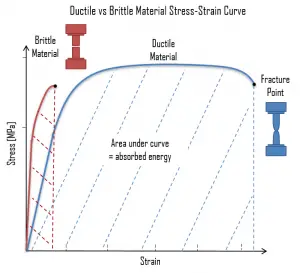

Toughness is the ability of a material to absorb energy and plastically deform without fracturing. One definition of toughness (or more specifically, fracture toughness) is that it is a property that is indicative of a material’s resistance to fracture when a crack (or other stress-concentrating defect) is present. Toughness is typically measured by the Charpy test or the Izod test. The impact test measures toughness under conditions of sudden loading and the presence of flaws such as notches or cracks which will concentrate stress at weak points. Toughness can also be defined with respect to regions of a stress–strain diagram. Toughness is related to the area under the stress–strain curve. The stress-strain curve measures toughness under gradually increasing load. In order to be tough, a material must be both strong and ductile. The following figure shows a typical stress-strain curve of a ductile material and a brittle material. For example, brittle materials (like ceramics) that are strong but with limited ductility are not tough; conversely, very ductile materials with low strengths are also not tough. To be tough, a material should withstand both high stresses and high strains.

Toughness is the ability of a material to absorb energy and plastically deform without fracturing. One definition of toughness (or more specifically, fracture toughness) is that it is a property that is indicative of a material’s resistance to fracture when a crack (or other stress-concentrating defect) is present. Toughness is typically measured by the Charpy test or the Izod test. The impact test measures toughness under conditions of sudden loading and the presence of flaws such as notches or cracks which will concentrate stress at weak points. Toughness can also be defined with respect to regions of a stress–strain diagram. Toughness is related to the area under the stress–strain curve. The stress-strain curve measures toughness under gradually increasing load. In order to be tough, a material must be both strong and ductile. The following figure shows a typical stress-strain curve of a ductile material and a brittle material. For example, brittle materials (like ceramics) that are strong but with limited ductility are not tough; conversely, very ductile materials with low strengths are also not tough. To be tough, a material should withstand both high stresses and high strains.

We hope, this article, Ductility and Toughness, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.