Aluminium alloys are based on aluminium, in which the main alloying elements are Cu, Mn, Si, Mg, Mg+Si, Zn. Aluminium alloy compositions are registered with The Aluminum Association. The aluminium alloys are divided into 9 families (Al1xxx to Al9xxx). The different families of alloys and the major alloying elements are:

Aluminium alloys are based on aluminium, in which the main alloying elements are Cu, Mn, Si, Mg, Mg+Si, Zn. Aluminium alloy compositions are registered with The Aluminum Association. The aluminium alloys are divided into 9 families (Al1xxx to Al9xxx). The different families of alloys and the major alloying elements are:

- 1xxx: no alloying elements

- 2xxx: Copper

- 3xxx: Manganese

- 4xxx: Silicon

- 5xxx: Magnesium

- 6xxx: Magnesium and silicon

- 7xxx: Zinc, magnesium, and copper

- 8xxx: other elements which are not covered by other series

There are also two principal classifications, namely casting alloys and wrought alloys, both of which are further subdivided into the categories heat-treatable and non-heat-treatable. Aluminium alloys containing alloying elements with limited solid solubility at room temperature and with a strong temperature dependence of solid solubility (for example Cu) can be strengthened by a suitable thermal treatment (precipitation hardening). The strength of heat treated commercial Al alloys exceeds 550 MPa.

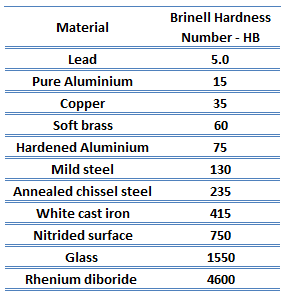

Hardness of Aluminium Alloys

Brinell hardness of 2024 aluminium alloy depends greatly on the temper of the material, but it is approximately 110 MPa.

Brinell hardness of 6061 aluminium alloy depends greatly on the temper of the material, but for T6 temper it is approximately 95 MPa.

Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). The minor load establishes the zero position. The major load is applied, then removed while still maintaining the minor load. The difference between depth of penetration before and after application of the major load is used to calculate the Rockwell hardness number. That is, the penetration depth and hardness are inversely proportional. The chief advantage of Rockwell hardness is its ability to display hardness values directly. The result is a dimensionless number noted as HRA, HRB, HRC, etc., where the last letter is the respective Rockwell scale.

The Rockwell C test is performed with a Brale penetrator (120°diamond cone) and a major load of 150kg.

We hope, this article, Hardness of Aluminium Alloys, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.