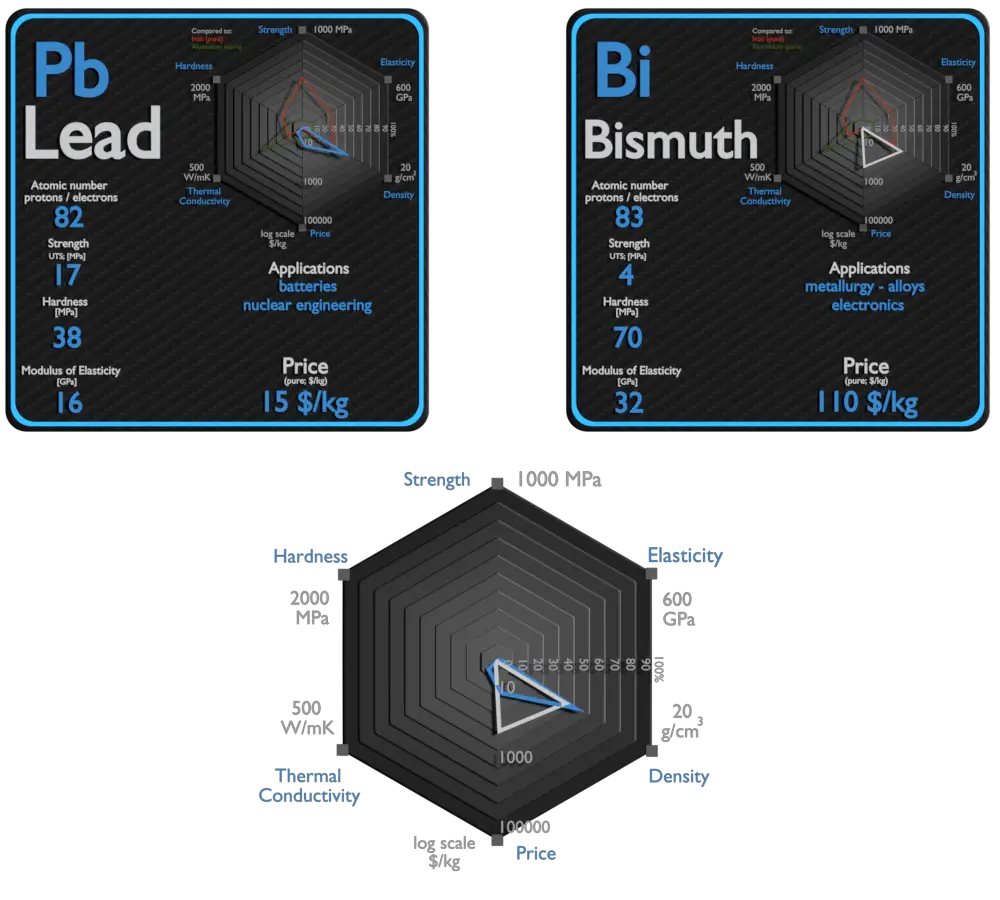

This article contains comparison of key thermal and atomic properties of lead and bismuth, two comparable chemical elements from the periodic table. It also contains basic descriptions and applications of both elements. Lead vs Bismuth.

Lead and Bismuth – About Elements

Source: www.luciteria.com

Lead and Bismuth – Applications

Lead

Lead metal has several useful mechanical properties, including high density, low melting point, ductility, and relative inertness. Lead is widely used for car batteries, pigments, ammunition, cable sheathing, weights for lifting, weight belts for diving, lead crystal glass, radiation protection and in some solders. The largest use of lead in the early 21st century is in lead–acid batteries. The lead in batteries undergoes no direct contact with humans, so there are fewer toxicity concerns. Lead is used in high voltage power cables as sheathing material to prevent water diffusion into insulation; this use is decreasing as lead is being phased out. A lead is widely used as a gamma shield. Major advantage of lead shield is in its compactness due to its higher density. On the other hand depleted uranium is much more effective due to its higher Z. Depleted uranium is used for shielding in portable gamma ray sources.

Bismuth

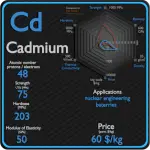

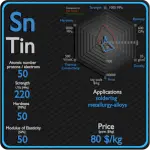

Bismuth metal is brittle and so it is usually mixed with other metals to make it useful. Its alloys with tin or cadmium have low melting points and are used in fire detectors and extinguishers, electric fuses and solders. Bismuth oxide is used as a yellow pigment for cosmetics and paints. Bismuth alloys are used in soldering, thermocouple materials and magnetic memory devices. Compounds of bismuth are used in lubricating greases, thermoelectric materials, infrared spectrometers. Bismuth oxychloride (BiOCl) is sometimes used in cosmetics, as a pigment in paint for eye shadows, hair sprays and nail polishes.

Lead and Bismuth – Comparison in Table

| Element | Lead | Bismuth |

| Density | 11.34 g/cm3 | 9.78 g/cm3 |

| Ultimate Tensile Strength | 17 MPa | 4 MPa |

| Yield Strength | 5.5 MPa | 2 MPa |

| Young’s Modulus of Elasticity | 16 GPa | 32 GPa |

| Mohs Scale | 1.5 | 2.5 |

| Brinell Hardness | 38 MPa | 70 MPa |

| Vickers Hardness | N/A | N/A |

| Melting Point | 327.5 °C | 271 °C |

| Boiling Point | 1740 °C | 1560 °C |

| Thermal Conductivity | 35 W/mK | 8 W/mK |

| Thermal Expansion Coefficient | 28.9 µm/mK | 13.4 µm/mK |

| Specific Heat | 0.13 J/g K | 0.12 J/g K |

| Heat of Fusion | 4.799 kJ/mol | 11.3 kJ/mol |

| Heat of Vaporization | 177.7 kJ/mol | 104.8 kJ/mol |