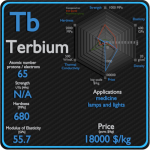

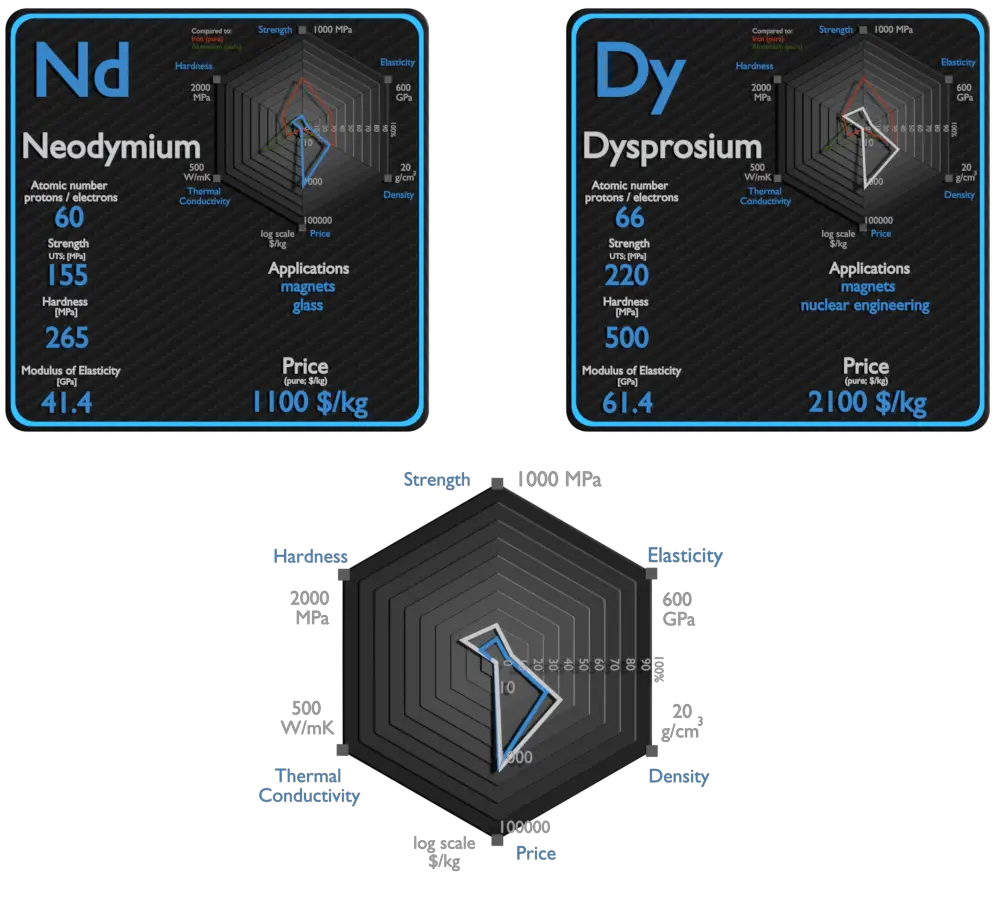

This article contains comparison of key thermal and atomic properties of neodymium and dysprosium, two comparable chemical elements from the periodic table. It also contains basic descriptions and applications of both elements. Neodymium vs Dysprosium.

Neodymium and Dysprosium – About Elements

Source: www.luciteria.com

Neodymium and Dysprosium – Applications

Neodymium

The most important use for neodymium is in an alloy with iron and boron to make very strong permanent magnets. These magnets are widely used in such products as microphones, professional loudspeakers, in-ear headphones, high performance hobby DC electric motors, and computer hard disks, where low magnet mass (or volume) or strong magnetic fields are required. Larger neodymium magnets are used in high-power-versus-weight electric motors (for example in hybrid cars) and generators (for example aircraft and wind turbine electric generators). Neodymium is a component, along with praseodymium, of didymium glass. This is a special glass for goggles used during glass blowing and welding. The element colours glass delicate shades of violet, wine-red and grey. Neodymium is also used in the glass for tanning booths, since it transmits the tanning UV rays but not the heating infrared rays.

Dysprosium

Dysprosium is utilized in ferrites and magnetic alloys for microwave use. Dysprosium is increasingly in demand for the permanent magnets used in electric-car motors and wind-turbine generators. Special stainless steels alloyed with dysprosium are used in nuclear control applications, that is, nuclear reactor control rods. The candidate of a new absorber material for accident-tollerant control rods includes gadolinia (Gd2O3), samaria (Sm2O3), europia (Eu2O3), dysprosia (Dy2O3), hafnia (HfO2).

Neodymium and Dysprosium – Comparison in Table

| Element | Neodymium | Dysprosium |

| Density | 7.01 g/cm3 | 8.551 g/cm3 |

| Ultimate Tensile Strength | 155 MPa | 220 MPa |

| Yield Strength | 150 MPa | 200 MPa |

| Young’s Modulus of Elasticity | 41.4 GPa | 61.4 GPa |

| Mohs Scale | N/A | N/A |

| Brinell Hardness | 265 MPa | 500 MPa |

| Vickers Hardness | 350 MPa | 550 MPa |

| Melting Point | 1016 °C | 1412 °C |

| Boiling Point | 3074 °C | 2567 °C |

| Thermal Conductivity | 17 W/mK | 11 W/mK |

| Thermal Expansion Coefficient | 9.6 µm/mK | 9.9 µm/mK |

| Specific Heat | 0.19 J/g K | 0.17 J/g K |

| Heat of Fusion | 7.14 kJ/mol | 11.06 kJ/mol |

| Heat of Vaporization | 273 kJ/mol | 230.1 kJ/mol |