High-speed steels, abbreviated as HSS, are a specialized class of tool steels that were named primarily for their ability to machine and cut materials at high speeds (high hot hardness). It is often used in power-saw blades and drill bits. High-speed steel is superior to the older high-carbon steel tools in that it can withstand higher temperatures without losing its temper (hardness). High-speed steels are complex iron-base alloys of carbon, chromium, vanadium, molybdenum, or tungsten, or combinations there of. To achieve good cutting performance from HSS, an appropriate hardening response must be provided in heat treatment.

Central to the performance of high-speed steels is the hardening response achieved during the heat treatment process. Alloying elements are introduced in quantities given by the intended application and by their function in the heat treatment process, whether to increase the solidus temperature or inhibit the growth of secondary hardening precipitates, enabling higher operating temperature.

Uses of AISI M2 Steel

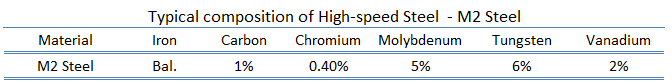

For example, molybdenum high-speed steel – AISI M2 is the “standard” and most widely used industrial HSS. Molybdenum high speed steels are designated as Group M steels according to the AISI classification system. M2 HSS has small and evenly distributed carbides giving high wear resistance, though its decarburization sensitivity is a little bit high. It is usually used to manufacture a variety of tools, such as drill bits, taps and reamers.

The carbon and alloy contents are balanced at sufficient levels to provide high attainable hardening response, excellent wear resistance, high resistance to the softening effects of elevated temperature, and good toughness for effective use in industrial cutting applications. Titanium nitride (an extremely hard ceramic material), or titanium carbide coatings can be used in the tools made of this kind of steels through physical vapor deposition process to improve the performance and life span of the tool. TiN has a Vickers hardness of 1800–2100 and it has metallic gold color.

We hope, this article, Uses of High-speed Steel – Application, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.