Alloys are usually stronger than pure metals, although they generally offer reduced electrical and thermal conductivity. Strength is the most important criterion by which many structural materials are judged. Therefore, alloys are used for engineering construction. Steel, probably the most common structural metal, is a good example of an alloy. It is an alloy of iron and carbon, with other elements to give it certain desirable properties.

It is sometimes possible for a material to be composed of several solid phases. The strengths of these materials are enhanced by allowing a solid structure to become a form composed of two interspersed phases. When the material in question is an alloy, it is possible to quench the metal from a molten state to form the interspersed phases. The term quenching refers to a heat treatment in which a material is rapidly cooled in water, oil or air to obtain certain material properties, especially hardness. In metallurgy, quenching is most commonly used to harden steel by introducing martensite.

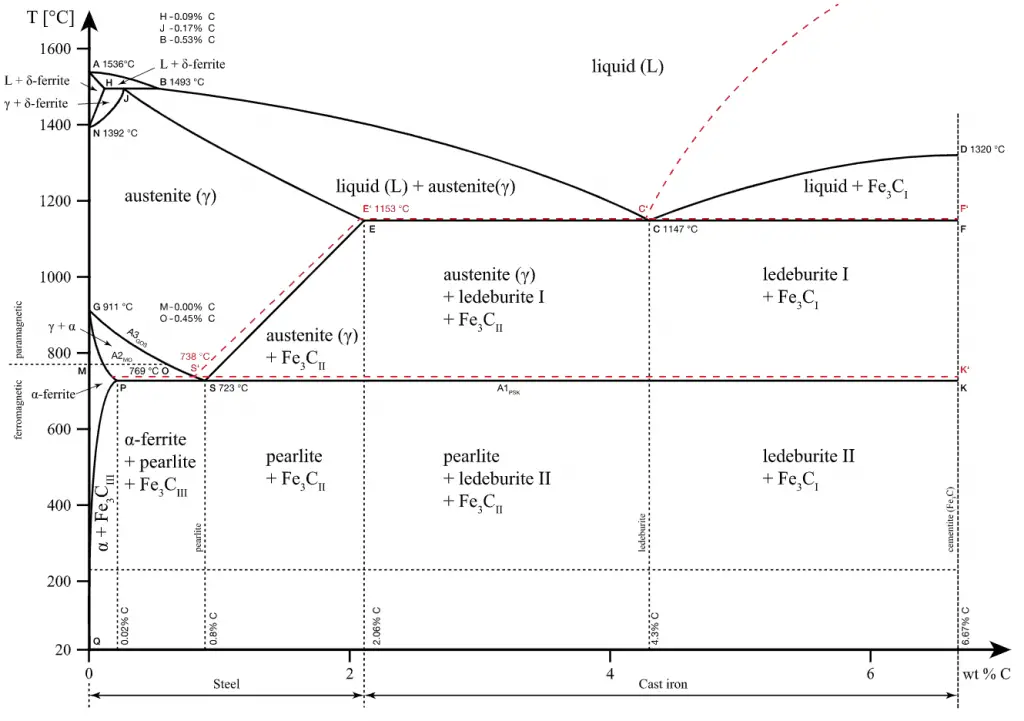

Ferrous alloys are known for their strength. Alloys are usually stronger than pure metals, although they generally offer reduced electrical and thermal conductivity. The simplest ferrous alloys are known as steels and they consist of iron (Fe) alloyed with carbon (C) (about 0.1% to 1%, depending on type). Adding a small amount of non-metallic carbon to iron trades its great ductility for the greater strength. Due to its very-high strength, but still substantial toughness, and its ability to be greatly altered by heat treatment, steel is one of the most useful and common ferrous alloy in modern use. Their widespread use is accounted for by following factors:

- Iron containing compounds exist in abundant quantities within the Earth’s crust.

- Metallic iron and steel alloys may be produced using relatively economical extraction, refining, alloying, and fabrication techniques

- Ferrous alloys are extremely versatile, in that they may be tailored to have a wide range of mechanical and physical properties.

The principal disadvantage of many ferrous alloys is their susceptibility to corrosion. By adding chromium to steel, its resistance to corrosion can be enhanced, creating stainless steel, while adding silicon will alter its electrical characteristics, producing silicon steel.

Types of Alloys

Metal alloys, by virtue of composition, are often grouped into two classes:

- Ferrous alloys. Ferrous alloys, those in which iron is the principal constituent, include steel, stainless steel, carbon steel, cast iron. Ferrous alloys are known for their strength.

- Non-ferrous alloys. Non-ferrous alloys those that does not contain iron (ferrite) in appreciable amounts thus they are based on non-ferrous metals (i.e. aluminium, copper, chromium, titanium, gold, nickel, silver, tin, lead, zinc, etc.) Other common properties of non-ferrous metals are non-magnetic, malleable, and lightweight.

We hope, this article, Characteristics of Metal Alloys, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.