Low-melting-point metals and alloys are somehow in opposition to refractory metals. Some low-melting-point alloys may be used as a solder, thus they are known as fusible alloys. A fusible alloy is a metal alloy capable of being easily fused, i.e. easily meltable, at relatively low temperatures.

Solder – Tin – Lead Eutectic Alloy

Soldering is a technique for joining metals using a filler metal alloy that has a melting temperature less than about 425°C (800°F). Because of this lower temperature and different alloys used as fillers, the metallurgical reaction between filler and work piece is minimal, resulting in a weaker joint. In electronics assembly, the eutectic alloy with 63% tin and 37% lead (or 60/40, which is almost identical in melting point) has been the alloy of choice. This eutectic alloy has melting point lower than those of either tin or lead.

Soldering is a technique for joining metals using a filler metal alloy that has a melting temperature less than about 425°C (800°F). Because of this lower temperature and different alloys used as fillers, the metallurgical reaction between filler and work piece is minimal, resulting in a weaker joint. In electronics assembly, the eutectic alloy with 63% tin and 37% lead (or 60/40, which is almost identical in melting point) has been the alloy of choice. This eutectic alloy has melting point lower than those of either tin or lead.

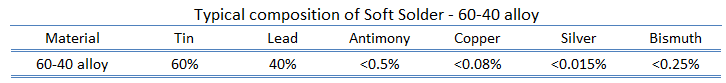

Tin is an important constituent in solders because it wets and adheres to many common base metals at temperatures considerably below their melting points. Small amounts of various metals, notably antimony and silver, are added to tin-lead solders to increase their strength. 60-40 solder provides strong and reliable joints under a variety of environmental conditions. There are also high-tin solders, which are used for joining parts of electrical apparatuses because their electrical conductivity is higher than that of high-lead solders. These solders are also used where lead may be a hazard, for example, in contact with drinking water or food.

Lead Alloys

Lead is a heavy metal that is denser than most common materials. Lead is soft and malleable, and has a relatively low melting point. Lead is widely used as a gamma shield. Major advantage of lead shield is in its compactness due to its higher density. It has high corrosion resistance, malleability, unusual electrical properties, and the ability to form useful alloys. Representative uses include: shielding agent against x-ray and gamma radiation; diecast grids for batteries; coatings that prepare surfaces for soldering. On the other hand, lead is extremely toxic and poses certain environmental hazards.

Lead forms a wide range of low-melting alloys and readily alloys with tin in all proportions, forming the tin-lead solders used widely in industry. In nuclear industry, lead and lead-bismuth alloys can be used as a reactor coolant.

Lead and Lead-bismuth Eutectic

Lead, lead-bismuth eutectic, and other metals have also been proposed and occasionally used. The lead-cooled fast reactor is a nuclear reactor design that features a fast neutron spectrum and molten lead or lead-bismuth eutectic coolant. Lead-Bismuth Eutectic or LBE is a eutectic alloy of lead (44.5%) and bismuth (55.5%). Molten lead or lead-bismuth eutectic can be used as the primary coolant because lead and bismuth have low neutron absorption and relatively low melting points.

Melting and boiling points of lead and lead-bismuth eutectic mixture are:

- lead

- melting point – 327.5°C

- boiling point – 1749°C

- lead-bismuth – eutectic mixture

- melting point – 123.5°C

- boiling point – 1670°C

Zinc Alloys

Zinc is a brittle metal and has a relatively low melting point of 419 °C (787 °F), resists corrosion, is ductile and malleable, and is highly soluble in copper. Zinc and zinc alloys are used in the form of coatings, castings, rolled sheets, drawn wire, forgings, and extrusions. Other uses of zinc are as a major constituent in brassesm nickel-silver alloys, typewriter metal, soft and aluminium solder, and commercial bronze.

Alloys of zinc with small amounts of copper, aluminium, and magnesium are useful in die casting as well as spin casting, especially in the automotive, electrical, and hardware industries. Zinc alloys have low melting points, require relatively low heat input, do not require fluxing or protective atmospheres. Because of their high fluidity, zinc alloys can be cast in much thinner walls than other die castings alloys, and they can be die cast to tighter dimensional tolerances. These zinc alloys are marketed under the name Zamak. The name zamak is an acronym of the German names for the metals of which the alloys are composed: Zink (zinc), Aluminium, Magnesium and Kupfer (copper). The low melting point together with the low viscosity of the alloy makes possible the production of small and intricate shapes.

We hope, this article, Low-melting-point Metals – Fusible Alloys, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.