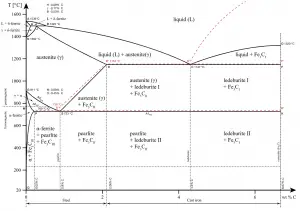

In materials engineering, cast irons are a class of ferrous alloys with carbon contents above 2.14 wt%. Typically, cast irons contain from 2.14 wt% to 4.0 wt% carbon and anywhere from 0.5 wt% to 3 wt% of silicon. Iron alloys with lower carbon content are known as steel. The difference is that cast irons can take advantage of eutectic solidification in the binary iron-carbon system. The term eutectic is Greek for “easy or well melting,” and the eutectic point represents the composition on the phase diagram where the lowest melting temperature is achieved. For the iron-carbon system the eutectic point occurs at a composition of 4.26 wt% C and a temperature of 1148°C.

Cast iron, therefore, has a lower melting point (between approximately 1150°C and 1300°C) than traditional steel, which makes it easier to cast than standard steels. Because of its high fluidity when molten, the liquid iron easily fills intricate molds and can form complex shapes. Most applications require very little finishing, so cast irons are used for a wide variety of small parts as well as large ones. It is an ideal material for sand casting into complex shapes such as exhaust manifolds without the need for extensive further machining. Furthermore, some cast irons are very brittle, and casting is the most convenient fabrication technique. Cast irons have become an engineering material with a wide range of applications and are used in pipes, machines and automotive industry parts, such as cylinder heads, cylinder blocks and gearbox cases. It is resistant to damage by oxidation.

Uses of Cast Iron – Application

Cast irons also comprise a large family of different types of iron, depending on how the carbon-rich phase forms during solidification. The microstructure of cast irons can be controlled to provide products that have excellent ductility, good machinability, excellent vibration damping, superb wear resistance, and good thermal conductivity. With proper alloying, the corrosion resistance of cast irons can equal that of stainless steels and nickel-base alloys in many services. For most cast irons, the carbon exists as graphite, and both microstructure and mechanical behavior depend on composition and heat treatment. The most common cast iron types are:

- Gray cast iron. Gray cast iron is the oldest and most common type of cast iron. Gray cast iron is characterised by its graphitic microstructure, which causes fractures of the material to have a gray appearance. This is due to the presence of graphite in its composition. In gray cast iron the graphite forms as flakes, taking on a three dimensional geometry. Gray cast iron have also an excellent damping capacity, which is given by the graphite because it absorbs the energy and converts it into heat. A large damping capacity is desirable for materials used in structures where unwanted vibrations are induced during operation such as machine tool bases or crankshafts. Materials like brass and steel have small damping capacities allowing vibration energy to be transmitted through them without attenuation.

- White cast iron. White cast irons are hard, brittle, and unmachinable, while gray irons with softer graphite are reasonably strong and machinable. A fracture surface of this alloy has a white appearance, and thus it is termed white cast iron. White iron is too brittle for use in many structural components, but with good hardness and abrasion resistance and relatively low cost, it finds use in such applications where wear resistance is desirable, such as on the teeth of excavators, impellers and volutes of slurry pumps, shell liners and lifter bars in ball mills.

- Malleable cast iron. Malleable cast iron is white cast iron that has been annealed. Through an annealing heat treatment, the brittle structure as first cast is transformed into the malleable form. Therefore, its composition is very similar to that of white cast iron, with slightly higher amounts of carbon and silicon. It is often used for small castings requiring good tensile strength and the ability to flex without breaking (ductility). Applications and uses of malleable cast irons include many essential automotive parts such as differential carriers, differential cases, bearing caps, steering-gear housings . Another uses include hand tools, brackets, machine parts, electrical fittings, pipe fittings, farm equipment and mining hardware.

Ductile iron is stronger and more shock resistant than gray iron. In fact, ductile iron has mechanical characteristics approaching those of steel, while it retains high fluidity when molten and lower melting point. - Ductile cast iron. Ductile iron, also known as nodular iron, is very similar to gray iron in composition, but during solidification the graphite nucleates as spherical particles (nodules) in ductile iron, rather than as flakes. Ductile iron is stronger and more shock resistant than gray iron. In fact, ductile iron has mechanical characteristics approaching those of steel, while it retains high fluidity when molten and lower melting point. Typical applications for this material include valves, pump bodies, crankshafts, gears, and other automotive and machine components because of its good machinability, fatigue strength, and higher modulus of elasticity (compared to gray iron), and in heavy-duty gears because of its high yield strength and wear resistance.

We hope, this article, Uses of Cast Iron – Application, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.