The bronzes are a family of copper-based alloys traditionally alloyed with tin, but can refer to alloys of copper and other elements (e.g. aluminum, silicon, and nickel). Bronzes are somewhat stronger than the brasses, yet they still have a high degree of corrosion resistance. Generally they are used when, in addition to corrosion resistance, good tensile properties are required. For example, beryllium copper attains the greatest strength (to 1,400 MPa) of any copper-based alloy.

The bronzes are a family of copper-based alloys traditionally alloyed with tin, but can refer to alloys of copper and other elements (e.g. aluminum, silicon, and nickel). Bronzes are somewhat stronger than the brasses, yet they still have a high degree of corrosion resistance. Generally they are used when, in addition to corrosion resistance, good tensile properties are required. For example, beryllium copper attains the greatest strength (to 1,400 MPa) of any copper-based alloy.

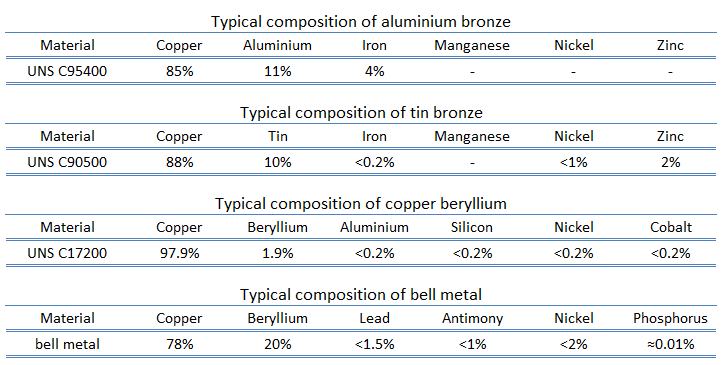

Composition of Bronzes

As was written, bronzes are a family of copper-based alloys traditionally alloyed with tin, but can refer to alloys of copper and other elements (e.g. aluminum, silicon, and nickel).

Tin and Phosphor Bronze. In general, bronzes are a family of copper-based alloys traditionally alloyed with tin, commonly with about 12–12.5% tin. The addition of small amounts (0.01–0.45) of phosphorus further increases the hardness, fatigue resistance and wear resistance. Addition of these alloyants leads to applications such as springs, fasteners, masonry fixings, shafts, valve spindles, gears and bearings. Bronze is also the preferred metal for bells in the form of a high tin bronze alloy known colloquially as bell metal, which is about 23% tin. High tin bronze alloys are typically found in also gears as well as high-strength bushing and bearing applications where high strength, and heavy loads are present. Other applications for these alloys are pump impellers, piston rings, and steam fittings. For example, copper casting alloy UNS C90500 is a cast alloy of copper-tin, which is also known as gun metal. Originally used chiefly for making guns, it has largely been replaced by steel.

Tin and Phosphor Bronze. In general, bronzes are a family of copper-based alloys traditionally alloyed with tin, commonly with about 12–12.5% tin. The addition of small amounts (0.01–0.45) of phosphorus further increases the hardness, fatigue resistance and wear resistance. Addition of these alloyants leads to applications such as springs, fasteners, masonry fixings, shafts, valve spindles, gears and bearings. Bronze is also the preferred metal for bells in the form of a high tin bronze alloy known colloquially as bell metal, which is about 23% tin. High tin bronze alloys are typically found in also gears as well as high-strength bushing and bearing applications where high strength, and heavy loads are present. Other applications for these alloys are pump impellers, piston rings, and steam fittings. For example, copper casting alloy UNS C90500 is a cast alloy of copper-tin, which is also known as gun metal. Originally used chiefly for making guns, it has largely been replaced by steel.- Silicon Bronze. Silicon bronze usually contains about 96 percent copper. Silicon bronze has a composition of Si: 2.80–3.80%, Mn: 0.50–1.30%, Fe: 0.80% max., Zn: 1.50% max., Pb: 0.05% max. Silicon bronzes have a good combination of strength and ductility, good corrosion resistance and easy weldability. Silicon bronzes were developed originally for the chemical industry because of their exceptional resistance to corrosion in many liquids. They are used in architectural product applications such as:

- Door fittings

- Railings

- Church doors

- Window frames

- Aluminium Bronze. The aluminum bronzes are a family of copper-based alloys offering a combination of mechanical and chemical properties unmatched by any other alloy series. They contain about 5 to 12% of aluminium. In addition, aluminium bronzes also contain nickel, silicon, manganese, and iron. They have excellent strength, similar to that of low alloy steels, and excellent corrosion resistance especially in seawater and similar environments, where the alloys often outperform many stainless steels. Their excellent resistance to corrosion results from the aluminium in the alloys, which reacts with atmospheric oxygen to form a thin, tough surface layer of alumina (aluminium oxide) which acts as a barrier to corrosion of the copper-rich alloy. They are found in wrought and cast form. Aluminium bronzes are usually golden in color. Aluminium bronzes are used in sea water applications that include:

- General sea water-related services

- Bearings

- Pipe fittings

- Pumps and valve components

- Heat exchangers

- Beryllium Bronze. Copper beryllium, also known as berylium bronze, is a copper alloy with 0.5—3% beryllium. Copper beryllium is the hardest and strongest of any copper alloy (UTS up to 1,400 MPa), in the fully heat treated and cold worked condition. It combines high strength with non-magnetic and non-sparking qualities and it is similar in mechanical properties to many high strength alloy steels but, compared to steels, it has better corrosion resistance. It has good thermal conductivity (210 W/m°C) 3-5 times more than tool steel. These high performance alloys have long been used for non-sparking tools in the mining (coal mines), gas and petrochemical industries (oil rigs). Beryllium copper screwdrivers, pliers, wrenches, cold chisels, knives, and hammers are available for these environments. Because of the excellent fatigue resistance, copper beryllium is widely used for springs, spring wire, load cells, and other parts that must retain their shape under cyclic loads.

- Bell Metal (High-tin Bronze). In general, bell metals refer usually to a high-tin bronzes that are a family of copper-based alloys traditionally alloyed with tin, commonly with more than 20% of tin (typically, 78% copper, 22% tin by mass). Bell metal is used for the casting of high-quality bells. The higher tin content increases the rigidity of the metal, and increases the resonance. It has been found that increasing the tin content increases the decay time of the bell strike, thus making the bell more sonorous. High-tin bronzes are also found in also gears as well as high-strength bushing and bearing applications where high strength, and heavy loads are present.

We hope, this article, Composition of Bronzes, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.