Low-alloy steels constitute a category of ferrous materials that exhibit mechanical properties superior to plain carbon steels resulting from additions of such alloying elements as nickel, chromium, and molybdenum, manganese, and silicon. The role of the alloying elements is to increase hardenability in order to optimize mechanical properties and toughness after heat treatment. In some cases, however, alloy additions are used to reduce environmental degradation under certain specified service conditions. Low-alloy steels may be classified into four major groups:

Low-alloy steels constitute a category of ferrous materials that exhibit mechanical properties superior to plain carbon steels resulting from additions of such alloying elements as nickel, chromium, and molybdenum, manganese, and silicon. The role of the alloying elements is to increase hardenability in order to optimize mechanical properties and toughness after heat treatment. In some cases, however, alloy additions are used to reduce environmental degradation under certain specified service conditions. Low-alloy steels may be classified into four major groups:

- low-carbon quenched and tempered (QT) steels

- medium-carbon ultrahigh-strength steels

- bearing steels

- heat-resistant chromium-molybdenum steels

41xx steel – Chromoly Steel – Medium-carbon Ultrahigh-strength Steels

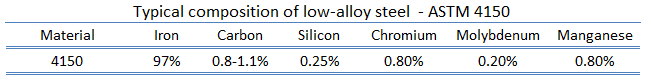

Chromoly steel is medium-carbon ultrahigh-strength low alloy steel that gets its name from a combination of the words “chromium” and “molybdenum” – two of the major alloying elements. Chromoly steel is often used when more strength is required than that of mild carbon steel, though it often comes at an increase in cost. Chromoly falls under the AISI 41xx steel designations (ASTM A519). Examples of applications for 4130, 4140 and 4145 include structural tubing, bicycle frames, crank shafts, chain links, drill collars, gas bottles for transportation of pressurized gases, firearm parts, clutch and flywheel components, and roll cages.

We hope, this article, Composition of Low-alloy Steel – Chromoly Steel, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.