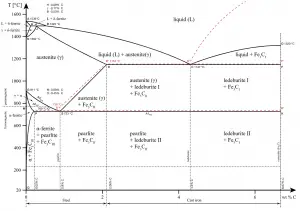

In materials engineering, cast irons are a class of ferrous alloys with carbon contents above 2.14 wt%. Typically, cast irons contain from 2.14 wt% to 4.0 wt% carbon and anywhere from 0.5 wt% to 3 wt% of silicon. Iron alloys with lower carbon content are known as steel. The difference is that cast irons can take advantage of eutectic solidification in the binary iron-carbon system. The term eutectic is Greek for “easy or well melting,” and the eutectic point represents the composition on the phase diagram where the lowest melting temperature is achieved. For the iron-carbon system the eutectic point occurs at a composition of 4.26 wt% C and a temperature of 1148°C.

See also: Types of Cast Irons

Malleable Cast Iron

Malleable cast iron is white cast iron that has been annealed. Through an annealing heat treatment, the brittle structure as first cast is transformed into the malleable form. Therefore, its composition is very similar to that of white cast iron, with slightly higher amounts of carbon and silicon. Malleable iron contains graphite nodules that are not truly spherical as they are in ductile iron, because they are formed as a result of heat treatment rather than forming during cooling from the melt. Malleable iron is made by first casting a white iron so that flakes of graphite are avoided and all the undissolved carbon is in the form of iron carbide. Malleable iron starts as a white iron casting that is then heat treated for a day or two at about 950 °C (1,740 °F) and then cooled over a day or two. As a result, the carbon in iron carbide transforms into graphite nodules surrounded by a ferrite or pearlite matrix, depending on cooling rate. The slow process allows the surface tension to form the graphite nodules rather than flakes. . Malleable iron, like ductile iron, possesses considerable ductility and toughness because of its combination of nodular graphite and low carbon metallic matrix. Like ductile iron, malleable iron also exhibits high resistance to corrosion, excellent machinability. The good damping capacity and fatigue strength of malleable iron are also useful for long service in highly stressed parts. There are two types of ferritic malleable iron: blackheart and whiteheart.

It is often used for small castings requiring good tensile strength and the ability to flex without breaking (ductility). Applications of malleable cast irons include many essential automotive parts such as differential carriers, differential cases, bearing caps, steering-gear housings . Another uses include hand tools, brackets, machine parts, electrical fittings, pipe fittings, farm equipment and mining hardware.

We hope, this article, Composition of Malleable Cast Iron, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.