Creep, known also as cold flow, is the permanent deformation that increases with time under constant load or stress. It results due to long time exposure to large external mechanical stress with in limit of yielding and is more severe in material that are subjected to heat for long time. The rate of deformation is a function of the material’s properties, exposure time, exposure thermodynamics/thermodynamic-properties/what-is-temperature-physics/”>temperature and the applied structural load. Creep is a very important phenomenon if we are using materials at high temperature. Creep is very important in power industry and it is of the highest importance in designing of jet engines. For many relatively short-life creep situations (e.g. turbine blades in military aircraft), time to rupture is the dominant design consideration. Of course, for its determination, creep tests must be conducted to the point of failure; these are termed creep rupture tests.

Creep becomes a problem when the stress intensity is approaching the fracture failure strength. If the creep rate increases rapidly, the strain becomes so large that it could result in failure. The creep rate is controlled by minimizing the stress and temperature of a material. Creep is more severe in materials that are subjected to heat for long periods and generally increases as they near their melting point. It is observed in all materials types; for metals, it becomes important only for temperatures greater than about 0.4Tm, where Tm is the absolute melting temperature.

For example, creep caused failure is an important failure mode of turbine blades of an aircraft engine. In this case, a turbine blade will cause the blade to contact the casing, resulting in the failure of the blade and the engine.

Stages of Creep

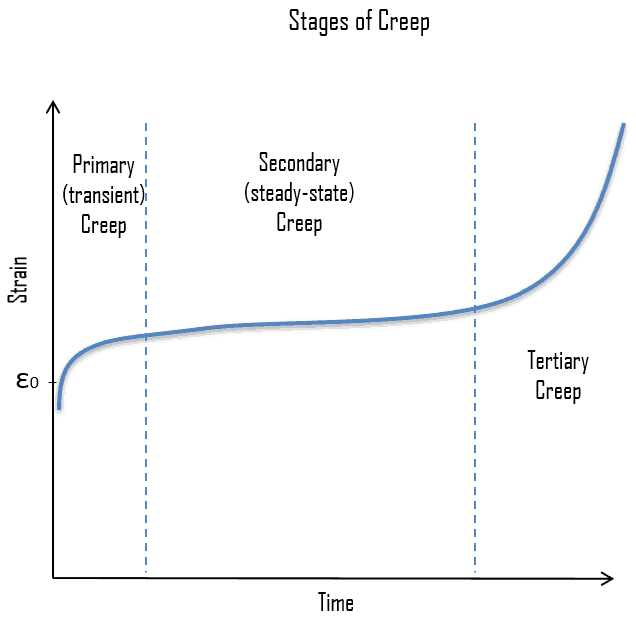

As can be seen from the figure, creep is time dependent and it goes through several stages:

- Primary Creep. In the initial stage, or primary creep, or transient creep, the strain rate is relatively high, but decreases with increasing time and strain due the fact that the material is experiencing an increase in creep resistance or strain hardening. This is followed by secondary (or steady-state) creep in Stage II, when the creep rate is small and the strain increases very slowly with time.

- Secondary Creep. For secondary creep, sometimes termed steady-state creep, the rate is constant—that is, the plot becomes nearly linear. The strain rate diminishes to a minimum and becomes near constant as the secondary stage begins. This is due to the balance between work hardening and annealing (thermal softening). This stage of creep is the most understood. The steady-state creep is often the stage of creep that is of the longest duration. No material strength is lost during these first two stages of creep. In materials engineering, possibly the most important parameter from a creep test is the slope of the secondary portion of the creep curve (ΔP/Δt). It is the engineering design parameter that is considered for long-life applications. This parameter is often called the minimum or steady-state creep rate.

- Tertiary Creep. In tertiary creep, there is an acceleration of the rate and possibly ultimate failure. The strain rate exponentially increases with stress because of necking phenomena or internal cracks, cavities or voids decrease the effective area of the specimen. These all lead to a decrease in the effective cross-sectional area and an increase in strain rate. Strength is quickly lost in this stage while the material’s shape is permanently changed. The acceleration of creep deformation in the tertiary stage eventually leads to failure, which is frequently termed rupture and results from microstructural and/or metallurgical changes.

Creep Prevention

Creep prevention is based on the proper choice of material is also crucial. Creep resistance of materials can be influenced by many factors such as diffusivity, precipitate and grain size. In general, there are three general ways to prevent creep in metal. One way is to use higher melting point metals, the second way is to use materials with greater grain size and the third way is to use alloying. Body-centered cubic (BCC) metals are less creep resistant in high temperatures. Therefore, superalloys (typically face-centered cubic austenitic alloys) based on Co, Ni, and Fe are capable of being engineered to be highly resistant to creep, and have thus arisen as an ideal material in high-temperature environments.

For device of selected material, it is of the highest importance to operate the device within limits, which are especially maximum service temperature and stress. The rate of creep is highly dependent on both stress and temperature. With most of the engineering alloys used in construction at room temperature or lower, creep strain is so small at working loads that it can safely be ignored. However, as temperature rises creep becomes progressively more important and eventually supersedes fatigue as the likely criterion for failure. The temperature at which creep becomes important will vary with the material. For safe operation, the total deformation due to creep must be well below the strain at which failure occurs.

We hope, this article, Creep – Material Creep, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.