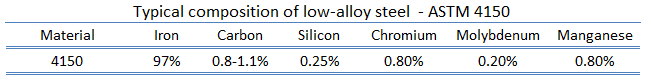

Low-alloy steels constitute a category of ferrous materials that exhibit mechanical properties superior to plain carbon steels resulting from additions of such alloying elements as nickel, chromium, and molybdenum, manganese, and silicon. The role of the alloying elements is to increase hardenability in order to optimize mechanical properties and toughness after heat treatment. In some cases, however, alloy additions are used to reduce environmental degradation under certain specified service conditions. Low-alloy steels may be classified into four major groups:

Low-alloy steels constitute a category of ferrous materials that exhibit mechanical properties superior to plain carbon steels resulting from additions of such alloying elements as nickel, chromium, and molybdenum, manganese, and silicon. The role of the alloying elements is to increase hardenability in order to optimize mechanical properties and toughness after heat treatment. In some cases, however, alloy additions are used to reduce environmental degradation under certain specified service conditions. Low-alloy steels may be classified into four major groups:

- low-carbon quenched and tempered (QT) steels

- medium-carbon ultrahigh-strength steels

- bearing steels

- heat-resistant chromium-molybdenum steels

41xx steel – Chromoly Steel – Medium-carbon Ultrahigh-strength Steels

Chromoly steel is medium-carbon ultrahigh-strength low alloy steel that gets its name from a combination of the words “chromium” and “molybdenum” – two of the major alloying elements. Chromoly steel is often used when more strength is required than that of mild carbon steel, though it often comes at an increase in cost. Chromoly falls under the AISI 41xx steel designations (ASTM A519). Examples of applications for 4130, 4140 and 4145 include structural tubing, bicycle frames, crank shafts, chain links, drill collars, gas bottles for transportation of pressurized gases, firearm parts, clutch and flywheel components, and roll cages.

Hardness of 41xx steel – Chromoly Steel

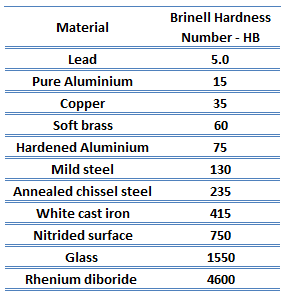

Brinell hardness of low-alloy steel – 41xx steel – chromoly steel is approximately 200 MPa.

In materials science, hardness is the ability to withstand surface indentation (localized plastic deformation) and scratching. Hardness is probably the most poorly defined material property because it may indicate resistance to scratching, resistance to abrasion, resistance to indentation or even resistance to shaping or localized plastic deformation. Hardness is important from an engineering standpoint because resistance to wear by either friction or erosion by steam, oil, and water generally increases with hardness.

In materials science, hardness is the ability to withstand surface indentation (localized plastic deformation) and scratching. Hardness is probably the most poorly defined material property because it may indicate resistance to scratching, resistance to abrasion, resistance to indentation or even resistance to shaping or localized plastic deformation. Hardness is important from an engineering standpoint because resistance to wear by either friction or erosion by steam, oil, and water generally increases with hardness.

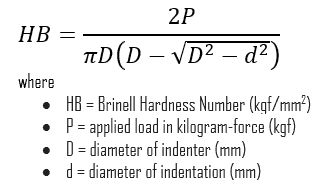

Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter hardened steel ball as an indenter with a 3,000 kgf (29.42 kN; 6,614 lbf) force. The load is maintained constant for a specified time (between 10 and 30 s). For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball.

The test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters.

The Brinell hardness number (HB) is the load divided by the surface area of the indentation. The diameter of the impression is measured with a microscope with a superimposed scale. The Brinell hardness number is computed from the equation:

There are a variety of test methods in common use (e.g. Brinell, Knoop, Vickers and Rockwell). There are tables that are available correlating the hardness numbers from the different test methods where correlation is applicable. In all scales, a high hardness number represents a hard metal.

We hope, this article, Hardness of Low-alloy Steel – 41xx steel – Chromoly Steel, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.