Pressure stresses are stresses induced in vessels containing pressurized materials. The loading is provided by the same force producing the pressure. Thermal stresses exist whenever temperature gradients are present in a material. Different temperatures produce different expansions and subject materials to internal stress. This type of stress is particularly noticeable in mechanisms operating at high temperatures that are cooled by a cold fluid. These stresses can be comprised of tensile stress, which is stress arising from forces acting in opposite directions tending to pull a material apart, and compressive stress, which is stress arising from forces acting in opposite directions tending to push a material together. These stresses, cyclic in nature, can lead to fatigue failure of the materials.

The reactor pressure vessel and piping, by contrast, are subjected to large load variations, but the cycle frequency is low; therefore, high ductility is the main requirement for the steel. Thermal sleeves are used in some cases, such as spray nozzles and surge lines, to minimize thermal stresses. Heatup and cooldown rate limits are based upon the impact on the future fatigue life of the plant. The heatup and cooldown limits ensure that the plant’s fatigue life is equal to or greater than the plant’s operational life. Additionally, plant design modifications include for example heating up of the Emergency Core Cooling System (ECCS) water tanks or sumps in order to reduce the temperature difference between injected water and tha material of RPV.

One safety issue that is a long-term problem brought on by the aging of nuclear facilities is pressurized thermal shock (PTS). PTS is the shock experienced by a thick-walled vessel due to the combined stresses from a rapid temperature and/or pressure change.

Special Reference: Reactor Pressure Vessel Status Report, U.S. NRC. NUREG-1511. Office of Nuclear Reactor Regulation U.S. Nuclear Regulatory Commission, Washington, 1994.

Pressure and Temperature (P/T) Limits

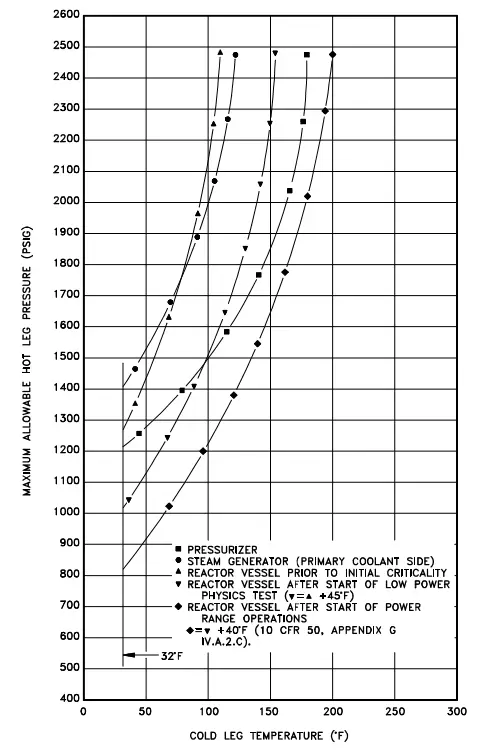

Pressure and temperature limits (P/T) are limiting curves defined in plant’s Technical Specification. Each P/T limit curve defines an acceptable region for normal operation. 10 CFR 50, Appendix G, requires the establishment of P/T limits for specific material fracture toughness requirements of the pressure boundary materials. The P-T limits are derived on the basis of linear elastic fracture mechanics (LEFM) analyses. In these analyses, the minimum temperature necessary to ensure adequate margins against RPV failure is determined as a function of pressure.

P/T are based on reactor vessel and head stress limitations and the need to preclude reactor vessel and head brittle fracture. The usual use of the curves is operational guidance during heatup or cooldown maneuvering, when pressure and temperature indications are monitored and compared to the applicable curve to determine that operation is within the allowable region. The curves used by operations also incorporate instrument error to ensure adequate safety margin. Because of the embrittling effects of neutron irradiation, the MPT curve will shift to the right over core life to account for the increased brittleness or decreased ductility.

Pressurized Thermal Shock – PTS

In general thermal shock is a mechanical load caused by a rapid change of temperature of a certain point. The change in temperature causes stresses on the surface that are in tension, which can encourage crack formation and propagation. Usually ceramics materials are usually susceptible to thermal shock, but under some circumstances also pressurized vessels suffer from thermal shocks. With rapid heating (or cooling) of a thick-walled vessel such as the reactor pressure vessel, one part of the wall may try to expand (or contract) while the adjacent section, which has not yet been exposed to the temperature change, tries to restrain it.

Pressurized Thermal Shock, PTS, means an event or transient in pressurized water reactors (PWRs) causing severe overcooling (thermal shock) concurrent with or followed by significant pressure in the reactor vessel. In this accident scenario, cold water enters a reactor while the vessel is pressurized. This rapidly cools the vessel and places large thermal stresses on the steel. Severe reactor system overcooling events that could be accompanied by pressurization or repressurization of the reactor vessel can result from a variety of causes. Pressure in the reactor system raises the severity of the thermal shock due to the addition of stress from pressure. Transients, which combine high system pressure and a severe thermal shock, are potentially more dangerous due to the added effect of the tensile stresses on the inside of the reactor vessel wall. PTS related transients include:

- stuck-open valves in the primary system,

- stuck-open valves in the secondary system,

- small-break loss-of-coolant accidents with subsequent injection of emergency core cooling system (ECCS) water,

- main steam line breaks,

- feedwater line breaks.

The NRC created 10 CFR Part 50.61 and 50.61a – the “PTS rule” and “alternate PTS rule” – to ensure the vessel’s steel remains strong enough to protect the vessel’s integrity. These rules require additional evaluations or other actions if embrittlement reaches certain limits.

RTNDT = RTNDT(U) + M + ΔRTNDT

where:

- RTNDT means the reference temperature for a reactor vessel material, under any conditions. For the reactor vessel beltline materials, RTNDT must account for the effects of neutron radiation.

- RTNDT(U) means the reference temperature for a reactor vessel material in the pre-service or unirradiated condition.

- ΔRTNDT is the increase in RTNDT caused by irradiation

- M is a margin added to cover uncertainties in the initial properties, copper and nickel contents, fluence, and calculation procedures. The greater the amounts of copper, nickel, and neutron fluence, the greater the increase.

As long as the fracture toughness of the reactor vessel material is relatively high, such events will not threaten RPV integrity. However, the fracture toughness of reactor vessel materials decreases with exposure to fast neutrons during the life of a nuclear power plant. If the fracture toughness of the vessel material has been reduced sufficiently, severe PTS events could cause propagation of small flaws that might exist near the inner surface of the vessel. The assumed initial flaw might propagate into a crack through the vessel wall of sufficient extent to threaten vessel integrity and, therefore, core cooling capability.

While PTS doesn’t affect boiling-water reactors, there are very limited conditions where those vessels could overpressurize at low temperatures.

Special Reference: NUREG-1511, Reactor Pressure Vessel Status Report. U.S. Nuclear Regulatory Commission, Washington, DC, 1994.

Special Reference: DOE FUNDAMENTALS HANDBOOK MATERIAL SCIENCE Volume 2 of 2, DOE-HDBK-1017/2-93, Washington, DC, 1993.

We hope, this article, Pressure and Temperature Stress, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.