Non-destructive testing, NDT, is a very broad group of structural or material inspections and as the name implies, these inspections do not destroy the material/structure being examined. NDT plays a critical role in assuring that structural components and systems perform their function in a reliable and cost effective fashion. Because NDT does not permanently alter the article being inspected, it is a highly valuable technique that can save both money and time in product evaluation, troubleshooting, and research. NDT technicians and engineers define and implement tests that locate and characterize material conditions and flaws that might otherwise cause serious accidents such as, planes to crash, reactors to fail, trains to derail, pipelines to burst, and a variety of troubling events.

This concept is extended, and known as Non-Destructive Evaluation (NDE), when combined with an assessment of the significance of any defects found. However, they are both terms often used interchangeably. Some testing methods must be conducted in a laboratory setting, others may be adapted for use in the field. Several commonly employed NDT techniques and their characteristics are described below.

Ultrasonic Testing

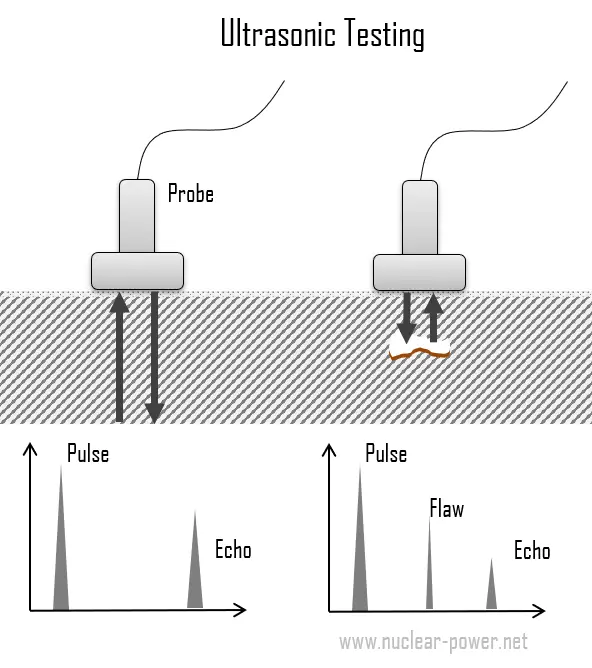

Ultrasonic testing is a broad group of NDT techniques based on the propagation of ultrasonic waves in the object or material tested. The most commonly used ultrasonic testing technique is pulse echo, wherein high-frequency sound wave beams (normally ranging from 1-5 MHz) is introduced into a test object and reflections (echoes) are returned to a receiver from internal imperfections or from the part’s geometrical surfaces.

Ultrasonic testing is a broad group of NDT techniques based on the propagation of ultrasonic waves in the object or material tested. The most commonly used ultrasonic testing technique is pulse echo, wherein high-frequency sound wave beams (normally ranging from 1-5 MHz) is introduced into a test object and reflections (echoes) are returned to a receiver from internal imperfections or from the part’s geometrical surfaces.

The basic method of ultrasonic testing is transforming a voltage pulse to an ultrasonic pulse using a transducer. Transducers used for traditional UT consist of a piezoelectric crystal enclosed within a plastic or stainless steel housing. The piezoelectric crystals expand when electrically charged, thus generating an acoustic wave. The signal travels through the object with respect to its geometry and existing defects and then is either transmitted to another transducer or reflected back to the original transducer. Defects are detected if they produce a change in the acoustic impedance in the path of the ultrasonic beam. An open crack filled with air has very low acoustic impedance so it reflects virtually all the acoustic energy incident on it. Hence, the sound waves travel through the material and are reflected back from cracks or flaws. Defects and flaws affect its way and a small portion of the pulse will be sent back to the transducer/receiver before it hits the end of the object.

Since the speed of sound in the parent material is known, the reflected sound energy is then displayed versus time and analyzed to define the presence and location of flaws or discontinuities.

Advantages and Disadvantages of Ultrasonic Testing

The advantages and disadvantages of ultrasonic testing method are as follows:

Advantages:

- UT is flexible, portable and has high penetration depth.

- High sensitivity, permitting the detection of extremely small flaws.

- It is applicable in wide range of industries

- Some capability of estimating the size, orientation, shape and nature of defects.

- Unlike radiographic testing, there is no health or environmental risk involved

Disadvantages:

- It requires highly-trained operators and requires careful attention by experienced technicians.

- Unable or not efficient in detecting planar defect that are in parallel with the direction of sound wave

- Parts that are rough, irregular in shape, very small or thin, or not homogeneous are difficult to inspect.

- Can be very expensive

We hope, this article, Ultrasonic Testing – Pulse-Echo Method, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.