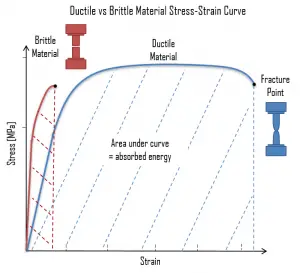

Toughness can be defined with respect to regions of a stress–strain diagram (for low-strain rate). Toughness is related to the area under the stress–strain curve. The stress-strain curve measures toughness under gradually increasing load. Tensile toughness is measured in units of joule per cubic metre (J·m−3) in the SI system. In order to be tough, a material must be both strong and ductile. The following figure shows a typical stress-strain curve of a ductile material and a brittle material. For example, brittle materials (like ceramics) that are strong but with limited ductility are not tough; conversely, very ductile materials with low strengths are also not tough. To be tough, a material should withstand both high stresses and high strains.

Toughness can be defined with respect to regions of a stress–strain diagram (for low-strain rate). Toughness is related to the area under the stress–strain curve. The stress-strain curve measures toughness under gradually increasing load. Tensile toughness is measured in units of joule per cubic metre (J·m−3) in the SI system. In order to be tough, a material must be both strong and ductile. The following figure shows a typical stress-strain curve of a ductile material and a brittle material. For example, brittle materials (like ceramics) that are strong but with limited ductility are not tough; conversely, very ductile materials with low strengths are also not tough. To be tough, a material should withstand both high stresses and high strains.

Notch Toughness

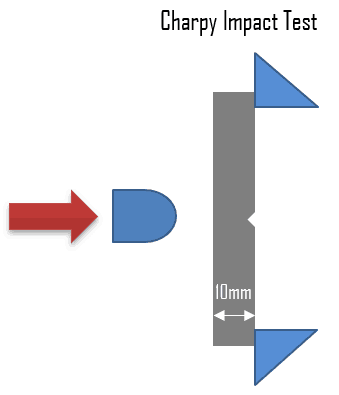

Notch toughness is measure of the energy absorbed (impact energy) during the fracture of a specimen (in the presence of a flaw – usually a V-notch) of standard dimensions and geometry when subjected to very rapid (impact) loading. As mentioned previously, in the presence of a flaw, such as a notch or crack, a material will likely exhibit a lower level of toughness. Charpy and Izod impact tests are used to measure this parameter, which is important in assessing the ductile-to-brittle transition behavior of a material. Similarly as for tensile toughness, notch toughness is measured in units of joule per cubic metre (J·m−3) in the SI system, but in this case we are measuring the area at the notch position.

Notch toughness is measure of the energy absorbed (impact energy) during the fracture of a specimen (in the presence of a flaw – usually a V-notch) of standard dimensions and geometry when subjected to very rapid (impact) loading. As mentioned previously, in the presence of a flaw, such as a notch or crack, a material will likely exhibit a lower level of toughness. Charpy and Izod impact tests are used to measure this parameter, which is important in assessing the ductile-to-brittle transition behavior of a material. Similarly as for tensile toughness, notch toughness is measured in units of joule per cubic metre (J·m−3) in the SI system, but in this case we are measuring the area at the notch position.

We hope, this article, Unit of Toughness, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.