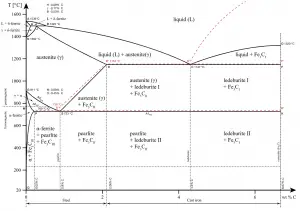

In materials engineering, cast irons are a class of ferrous alloys with carbon contents above 2.14 wt%. Typically, cast irons contain from 2.14 wt% to 4.0 wt% carbon and anywhere from 0.5 wt% to 3 wt% of silicon. Iron alloys with lower carbon content are known as steel. The difference is that cast irons can take advantage of eutectic solidification in the binary iron-carbon system. The term eutectic is Greek for “easy or well melting,” and the eutectic point represents the composition on the phase diagram where the lowest melting temperature is achieved. For the iron-carbon system the eutectic point occurs at a composition of 4.26 wt% C and a temperature of 1148°C.

See also: Types of Cast Irons

Ductile Cast Iron

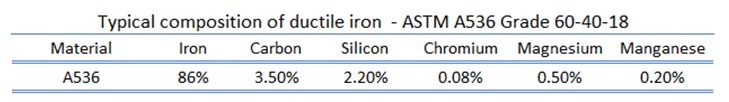

Ductile iron, also known as nodular iron or spheroidal graphite iron, is very similar to gray iron in composition, but during solidification the graphite nucleates as spherical particles (nodules) in ductile iron, rather than as flakes. Ductile iron is not a single material but part of a group of materials which can be produced with a wide range of properties through control of their microstructure. The matrix phase surrounding these particles is either pearlite or ferrite, depending on heat treatment. Ductile iron is stronger and more shock resistant than gray iron, so although it is more expensive due to alloyants, it may be the preferred economical choice because a lighter casting can perform the same function.

Although most versions of cast iron are often brittle, ductile cast iron has much greater fatigue and impact resistance due to its nodular graphite inclusions, which is the common defining characteristic of this group of materials. In ductile irons, graphite is in the form of nodules rather than flakes as in gray iron. Nodule formation is achieved by adding a small amount of magnesium or cerium to the alloy when in the liquid phase, the growth of graphite can be slowed during the solidification process. Whereas sharp graphite flakes create stress concentration points within the metal matrix, rounded nodules inhibit the creation of cracks, thus providing the enhanced ductility that gives the alloy its name. In fact, ductile iron has mechanical characteristics approaching those of steel, while it retains high fluidity when molten and lower melting point.

Typical applications for this material include valves, pump bodies, crankshafts, gears, and other automotive and machine components because of its good machinability, fatigue strength, and higher modulus of elasticity (compared to gray iron), and in heavy-duty gears because of its high yield strength and wear resistance.

We hope, this article, Composition of Ductile Cast Iron, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.