Light metals and its alloys are materials of relatively low density and high strength-to-weight ratios. These metals and alloys are of great importance in engineering applications for use in land, sea, air, and space transportation. Magnesium, aluminium and titanium are light metals of significant commercial importance. These three metals and their alloys comprise the bulk of the high strength-to-weight ratio metallic materials used in industrial systems. Aluminium is the most versatile of these materials and titanium is the most corrosion resistant with very high strength, while magnesium has the lowest density. Their densities of 1.7 (magnesium), 2.7 (aluminium) and 4.5 g/cm3 (titanium) range from 19 to 56% of the densities of the older structural metals, iron (7.9g/cm3) and copper (8.9 g/cm3). The metals commonly classed as light metals are those whose density is less than the density of steel (7.8 g/cm3, or 0.28 lb/in.3).

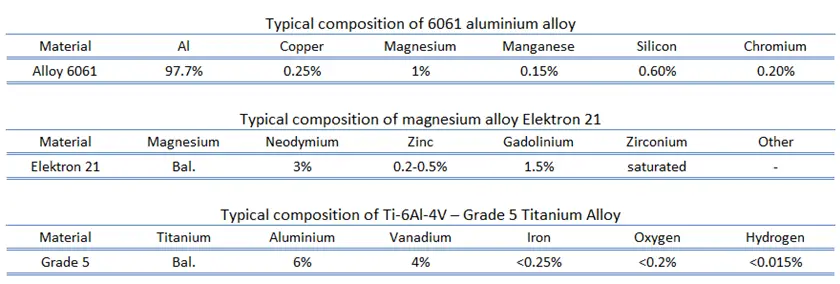

Since these pure metals are usually softer materials with insufficient strength, they must be alloyed to reach target mechanical properties. For example, high purity aluminium is a soft material with the ultimate strength of approximately 10 MPa, which limits its usability in industrial applications. On the other hand, tensile strength of 6061 aluminium alloy may reach more than 290 MPa depending on the temper of the material. Therefore, we are discussing primarily the alloys instead of pure metals.

Composition of Light Alloys

As was written, magnesium, aluminium and titanium are light metals of significant commercial importance. These three metals and their alloys comprise the bulk of the high strength-to-weight ratio metallic materials used in industrial systems. Aluminium is the most versatile of these materials and titanium is the most corrosion resistant with very high strength, while magnesium has the lowest density. In addition to these metals, beryllium is also a high-strength, lightweight metal with very high elastic modulus (303 GPa) that is finding increasing use as a structural material in aerospace vehicles. The elastic modulus of beryllium is nearly three times that of titanium.

Aluminium Alloys. Mechanical properties of aluminium alloys highly depend on their phase composition and microstructure. High strength can be achieved among others by introduction of a high volume fraction of fine, homogeneously distributed second phase particles and by a refinement of the grain size. In general, aluminium alloys are characterized by a relatively low density (2.7 g/cm3 as compared to 7.9 g/cm3 for steel), high electrical and thermal conductivities, and a resistance to corrosion in some common environments, including the ambient atmosphere. The chief limitation of aluminum is its low melting temperature (660°C), which restricts the maximum temperature at which it can be used. For general production the 5000 and 6000 series alloys provide adequate strength combined with good corrosion resistance, high toughness and ease of welding. Aluminium and its alloys are used widely in aerospace, automotive, architectural, lithographic, packaging, electrical and electronic applications.

Aluminium Alloys. Mechanical properties of aluminium alloys highly depend on their phase composition and microstructure. High strength can be achieved among others by introduction of a high volume fraction of fine, homogeneously distributed second phase particles and by a refinement of the grain size. In general, aluminium alloys are characterized by a relatively low density (2.7 g/cm3 as compared to 7.9 g/cm3 for steel), high electrical and thermal conductivities, and a resistance to corrosion in some common environments, including the ambient atmosphere. The chief limitation of aluminum is its low melting temperature (660°C), which restricts the maximum temperature at which it can be used. For general production the 5000 and 6000 series alloys provide adequate strength combined with good corrosion resistance, high toughness and ease of welding. Aluminium and its alloys are used widely in aerospace, automotive, architectural, lithographic, packaging, electrical and electronic applications. Magnesium Alloys. Magnesium alloys are mixtures of magnesium and other alloying metal, usually aluminium, zinc, silicon, manganese, copper and zirconium. Since the most outstanding characteristic of magnesium is its density, 1.7 g/cm3, its alloys are used where light weight is an important consideration (e.g., in aircraft components). Magnesium has the lowest melting (923 K (1,202 °F)) of all the alkaline earth metals. Magnesium alloys are typically used as cast alloys. Despite the reactive nature of the pure magnesium powder, magnesium metal and its alloys have good resistance to corrosion. We must add, pure magnesium is highly flammable, especially when powdered or shaved into thin strips, though it is difficult to ignite in mass or bulk. It produces intense, bright, white light when it burns. Flame temperatures of magnesium and some magnesium alloys can reach 3,100°C.

Magnesium Alloys. Magnesium alloys are mixtures of magnesium and other alloying metal, usually aluminium, zinc, silicon, manganese, copper and zirconium. Since the most outstanding characteristic of magnesium is its density, 1.7 g/cm3, its alloys are used where light weight is an important consideration (e.g., in aircraft components). Magnesium has the lowest melting (923 K (1,202 °F)) of all the alkaline earth metals. Magnesium alloys are typically used as cast alloys. Despite the reactive nature of the pure magnesium powder, magnesium metal and its alloys have good resistance to corrosion. We must add, pure magnesium is highly flammable, especially when powdered or shaved into thin strips, though it is difficult to ignite in mass or bulk. It produces intense, bright, white light when it burns. Flame temperatures of magnesium and some magnesium alloys can reach 3,100°C. Titanium Alloys. Titanium alloys are metals that contain a mixture of titanium and other chemical elements. Such alloys have very high tensile strength and toughness (even at extreme temperatures). They are light in weight, have extraordinary corrosion resistance and the ability to withstand extreme temperatures. Although “commercially pure” titanium has acceptable mechanical properties and has been used for orthopedic and dental implants, for most applications titanium is alloyed with small amounts of aluminium and vanadium, typically 6% and 4% respectively, by weight. This mixture has a solid solubility which varies dramatically with temperature, allowing it to undergo precipitation strengthening.

Titanium Alloys. Titanium alloys are metals that contain a mixture of titanium and other chemical elements. Such alloys have very high tensile strength and toughness (even at extreme temperatures). They are light in weight, have extraordinary corrosion resistance and the ability to withstand extreme temperatures. Although “commercially pure” titanium has acceptable mechanical properties and has been used for orthopedic and dental implants, for most applications titanium is alloyed with small amounts of aluminium and vanadium, typically 6% and 4% respectively, by weight. This mixture has a solid solubility which varies dramatically with temperature, allowing it to undergo precipitation strengthening.

We hope, this article, Composition of Light Metals and Alloys, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.