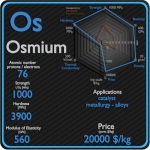

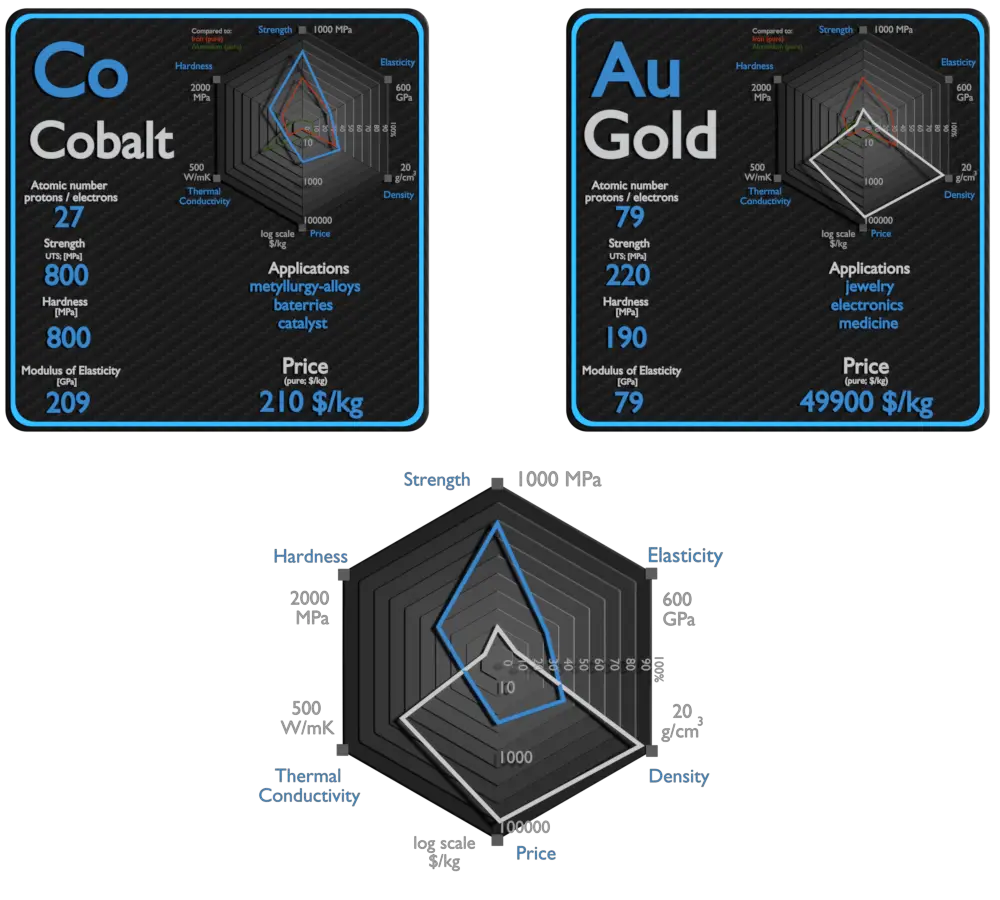

This article contains comparison of key thermal and atomic properties of cobalt and gold, two comparable chemical elements from the periodic table. It also contains basic descriptions and applications of both elements. Cobalt vs Gold.

Cobalt and Gold – About Elements

Source: www.luciteria.com

Cobalt and Gold – Applications

Cobalt

Cobalt has been used in many industrial, commercial, and military applications. Cobalt is primarily used in lithium-ion batteries, and in the manufacture of magnetic, wear-resistant and high-strength alloys. Cobalt-based Superalloys. This class of alloys is relatively new. In 2006, Sato et al. discovered a new phase in the Co–Al–W system. Unlike other superalloys, cobalt-base alloys are characterized by a solid-solution-strengthened austenitic (fcc) matrix in which a small quantity of carbide is distributed. While not used commercially to the extent of Ni-based superalloys, alloying elements found in research Co-based alloys are C, Cr, W, Ni, Ti, Al, Ir, and Ta. They possess better weldability and thermal fatigue resistance as compared to nickel based alloy. Moreover, they have excellent corrosion resistance at high temperatures (980-1100 °C) because of their higher chromium contents. Several cobalt compounds are oxidation catalysts. Typical catalysts are the cobalt carboxylates (known as cobalt soaps). They are also used in paints, varnishes, and inks as “drying agents” through the oxidation of drying oils.

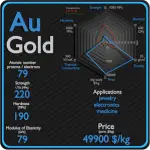

Gold

Gold is used extensively in jewellery, either in its pure form or as an alloy. About 75% of all gold produced is used in the jewelry industry. Pure gold is too soft to stand up to the stresses applied to many jewelry items. Craftsmen learned that alloying gold with other metals such as copper, silver, and platinum would increase its durability. The term ‘carat’ indicates the amount of gold present in an alloy. 24-carat is pure gold, but it is very soft. 18- and 9-carat gold alloys are commonly used because they are more durable. Gold’s high malleability, ductility, resistance to corrosion and most other chemical reactions, and conductivity of electricity have led to its continued use in corrosion resistant electrical connectors in all types of computerized devices (its chief industrial use). Gold is also used in infrared shielding, colored-glass production, gold leafing, and tooth restoration. Only 10% of the world consumption of new gold produced goes to industry, but by far the most important industrial use for new gold is in fabrication of corrosion-free electrical connectors in computers and other electrical devices.

Cobalt and Gold – Comparison in Table

| Element | Cobalt | Gold |

| Density | 8.9 g/cm3 | 19.3 g/cm3 |

| Ultimate Tensile Strength | 800 MPa | 220 MPa |

| Yield Strength | 220 MPa | 205 MPa |

| Young’s Modulus of Elasticity | 209 GPa | 75 GPa |

| Mohs Scale | 5 | 2.75 |

| Brinell Hardness | 800 MPa | 190 MPa |

| Vickers Hardness | 1040 MPa | 215 MPa |

| Melting Point | 1495 °C | 1064 °C |

| Boiling Point | 2927 °C | 2970 °C |

| Thermal Conductivity | 100 W/mK | 320 W/mK |

| Thermal Expansion Coefficient | 13 µm/mK | 14.2 µm/mK |

| Specific Heat | 0.42 J/g K | 0.128 J/g K |

| Heat of Fusion | 16.19 kJ/mol | 12.55 kJ/mol |

| Heat of Vaporization | 376.5 kJ/mol | 334.4 kJ/mol |