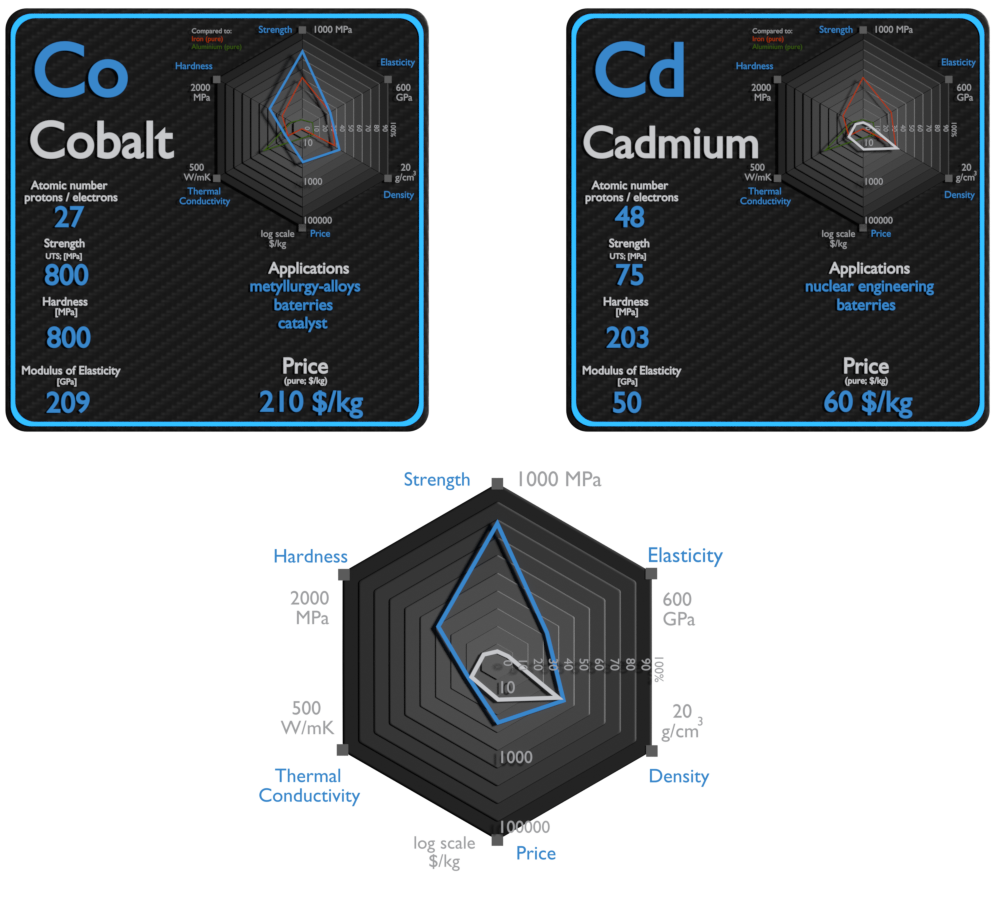

This article contains comparison of key thermal and atomic properties of cobalt and cadmium, two comparable chemical elements from the periodic table. It also contains basic descriptions and applications of both elements. Cobalt vs Cadmium.

Cobalt and Cadmium – About Elements

Source: www.luciteria.com

Cobalt and Cadmium – Applications

Cobalt

Cobalt has been used in many industrial, commercial, and military applications. Cobalt is primarily used in lithium-ion batteries, and in the manufacture of magnetic, wear-resistant and high-strength alloys. Cobalt-based Superalloys. This class of alloys is relatively new. In 2006, Sato et al. discovered a new phase in the Co–Al–W system. Unlike other superalloys, cobalt-base alloys are characterized by a solid-solution-strengthened austenitic (fcc) matrix in which a small quantity of carbide is distributed. While not used commercially to the extent of Ni-based superalloys, alloying elements found in research Co-based alloys are C, Cr, W, Ni, Ti, Al, Ir, and Ta. They possess better weldability and thermal fatigue resistance as compared to nickel based alloy. Moreover, they have excellent corrosion resistance at high temperatures (980-1100 °C) because of their higher chromium contents. Several cobalt compounds are oxidation catalysts. Typical catalysts are the cobalt carboxylates (known as cobalt soaps). They are also used in paints, varnishes, and inks as “drying agents” through the oxidation of drying oils.

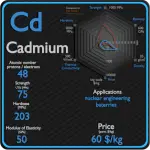

Cadmium

Cadmium is primarily consumed for the production of rechargeable nickel cadmium batteries. In 2009, 86% of cadmium was used in batteries, predominantly in rechargeable nickel-cadmium batteries. Other end uses include pigments, coatings and plating, and as stabilizers for plastics. Solar cell manufacturing may become another significant market for cadmium in the future. In nuclear industry cadmium is commonly used as a thermal neutron absorber due to very high neutron absorption cross-section of 113Cd. 113Cd has specific absorption cross-section.

Cobalt and Cadmium – Comparison in Table

| Element | Cobalt | Cadmium |

| Density | 8.9 g/cm3 | 8.65 g/cm3 |

| Ultimate Tensile Strength | 800 MPa | 75 MPa |

| Yield Strength | 220 MPa | N/A |

| Young’s Modulus of Elasticity | 209 GPa | 50 GPa |

| Mohs Scale | 5 | 2 |

| Brinell Hardness | 800 MPa | 203 MPa |

| Vickers Hardness | 1040 MPa | N/A |

| Melting Point | 1495 °C | 321.07 °C |

| Boiling Point | 2927 °C | 767 °C |

| Thermal Conductivity | 100 W/mK | 97 W/mK |

| Thermal Expansion Coefficient | 13 µm/mK | 30.8 µm/mK |

| Specific Heat | 0.42 J/g K | 0.23 J/g K |

| Heat of Fusion | 16.19 kJ/mol | 6.192 kJ/mol |

| Heat of Vaporization | 376.5 kJ/mol | 99.57 kJ/mol |