Malleable cast iron is white cast iron that has been annealed. Through an annealing heat treatment, the brittle structure as first cast is transformed into the malleable form. Therefore, its composition is very similar to that of white cast iron, with slightly higher amounts of carbon and silicon. Malleable iron contains graphite nodules that are not truly spherical as they are in ductile iron, because they are formed as a result of heat treatment rather than forming during cooling from the melt. Malleable iron is made by first casting a white iron so that flakes of graphite are avoided and all the undissolved carbon is in the form of iron carbide. Malleable iron starts as a white iron casting that is then heat treated for a day or two at about 950 °C (1,740 °F) and then cooled over a day or two. As a result, the carbon in iron carbide transforms into graphite nodules surrounded by a ferrite or pearlite matrix, depending on cooling rate. The slow process allows the surface tension to form the graphite nodules rather than flakes. . Malleable iron, like ductile iron, possesses considerable ductility and toughness because of its combination of nodular graphite and low carbon metallic matrix. Like ductile iron, malleable iron also exhibits high resistance to corrosion, excellent machinability. The good damping capacity and fatigue strength of malleable iron are also useful for long service in highly stressed parts. There are two types of ferritic malleable iron: blackheart and whiteheart.

It is often used for small castings requiring good tensile strength and the ability to flex without breaking (ductility). Applications of malleable cast irons include many essential automotive parts such as differential carriers, differential cases, bearing caps, steering-gear housings . Another uses include hand tools, brackets, machine parts, electrical fittings, pipe fittings, farm equipment and mining hardware.

Hardness of Malleable Cast Iron – ASTM A220

Brinell hardness of malleable cast iron – ASTM A220 is approximately 250 MPa.

In materials science, hardness is the ability to withstand surface indentation (localized plastic deformation) and scratching. Hardness is probably the most poorly defined material property because it may indicate resistance to scratching, resistance to abrasion, resistance to indentation or even resistance to shaping or localized plastic deformation. Hardness is important from an engineering standpoint because resistance to wear by either friction or erosion by steam, oil, and water generally increases with hardness.

In materials science, hardness is the ability to withstand surface indentation (localized plastic deformation) and scratching. Hardness is probably the most poorly defined material property because it may indicate resistance to scratching, resistance to abrasion, resistance to indentation or even resistance to shaping or localized plastic deformation. Hardness is important from an engineering standpoint because resistance to wear by either friction or erosion by steam, oil, and water generally increases with hardness.

Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested. The typical test uses a 10 mm (0.39 in) diameter hardened steel ball as an indenter with a 3,000 kgf (29.42 kN; 6,614 lbf) force. The load is maintained constant for a specified time (between 10 and 30 s). For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball.

The test provides numerical results to quantify the hardness of a material, which is expressed by the Brinell hardness number – HB. The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters.

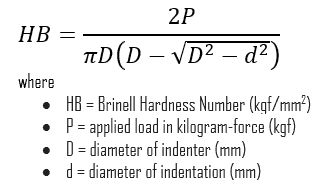

The Brinell hardness number (HB) is the load divided by the surface area of the indentation. The diameter of the impression is measured with a microscope with a superimposed scale. The Brinell hardness number is computed from the equation:

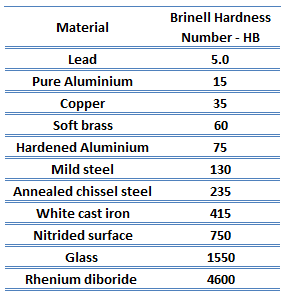

There are a variety of test methods in common use (e.g. Brinell, Knoop, Vickers and Rockwell). There are tables that are available correlating the hardness numbers from the different test methods where correlation is applicable. In all scales, a high hardness number represents a hard metal.

We hope, this article, Hardness of Malleable Cast Iron, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.