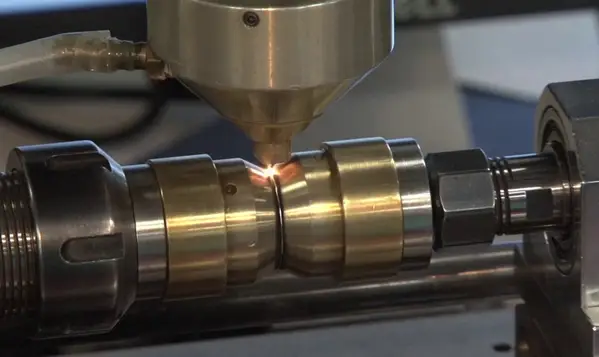

Laser beam welding is one of high-power-density welding processes (on the order of 1 MW/cm2), which utilize a very high rate of heat input. These processes usually require automation and have excellent potential for high-speed production. Laser beam welding uses effects the fusion welding of materials with the heat supplied by a laser beam that impinges on the joint. A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. For weldinf purposes, laser beam is coherent, monochromatic light in the infrared or ultraviolet frequency portion of the electromagnetic radiation spectrum. Therefore, the beam is invisible. Commercial carbon dioxide (CO2) lasers can emit many hundreds of watts in a single spatial mode which can be concentrated into a tiny spot. This emission is in the thermal infrared at 10.6 µm; such lasers are regularly used in industry for cutting and welding. The minimally divergent raw beam is focused into a small spotto obtain greatest power density.

Laser beam welding is one of high-power-density welding processes (on the order of 1 MW/cm2), which utilize a very high rate of heat input. These processes usually require automation and have excellent potential for high-speed production. Laser beam welding uses effects the fusion welding of materials with the heat supplied by a laser beam that impinges on the joint. A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. For weldinf purposes, laser beam is coherent, monochromatic light in the infrared or ultraviolet frequency portion of the electromagnetic radiation spectrum. Therefore, the beam is invisible. Commercial carbon dioxide (CO2) lasers can emit many hundreds of watts in a single spatial mode which can be concentrated into a tiny spot. This emission is in the thermal infrared at 10.6 µm; such lasers are regularly used in industry for cutting and welding. The minimally divergent raw beam is focused into a small spotto obtain greatest power density.

Laser Beam Welding – Advantages and Disadvantages

The main benefits include good flexibility, improved productivity with substantial saving on maintenance and energy cost while producing a strong weld. Metal sheets having thickness in the range 0.2 to 6mm can easily be laser welded. Majority of the automotive industries employ cross flow CO2 laser system in the power range of 3 to 5 kW. A special caution must be taken to personal safety. A safety enclosure is mandatory for protection against scattered radiation. The appropriate protective eyewear and clothing for the given type of laser must be used. Laser equipment is highly sophisticated and expensive, requiring knowledgeable personnel to install it and set parameters. Therefore this process requires automation and has excellent potential for high-speed production.

We hope, this article, Laser Beam Welding, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.