Surface Hardening – Case Hardening

Case hardening or surface hardening is the process in which hardness the surface (case) of an object is enhanced, while the inner core of the object remains elastic and tough. After this process surface hardness, wear-resistance and fatigue life are enhanced. This is accomplished by several processes such as a carburizing or nitriding process by which a component is exposed to a carbonaceous or nitrogenous atmosphere at elevated temperature. As was written, two main material characteristics are influenced:

- Hardness and wear resistance is significantly enhanced. In materials science, hardness is the ability to withstand surface indentation (localized plastic deformation) and scratching. Hardness is probably the most poorly defined material property because it may indicate resistance to scratching, resistance to abrasion, resistance to indentation or even resistance to shaping or localized plastic deformation. Hardness is important from an engineering standpoint because resistance to wear by either friction or erosion by steam, oil, and water generally increases with hardness.

- Toughness is not negatively influenced. Toughness is the ability of a material to absorb energy and plastically deform without fracturing. One definition of toughness (for high-strain rate, fracture toughness) is that it is a property that is indicative of a material’s resistance to fracture when a crack (or other stress-concentrating defect) is present.

For iron or steel with low carbon content, which has poor to no hardenability of its own, the case-hardening process involves infusing additional carbon or nitrogen into the surface layer. Case hardening is useful in parts such as a cam or ring gear that must have a very hard surface to resist wear, along with a tough interior to resist the impact that occurs during operation. Further, the surface hardening of steel has an advantage over through hardening (that is, hardening the metal uniformly throughout the piece) because less expensive low-carbon and medium-carbon steels can be surface hardened without the problems of distortion and cracking associated with the through hardening of thick sections. A carbon- or nitrogen-rich outer surface layer (or case) is introduced by atomic diffusion from the gaseous phase. The case is normally on the order of 1 mm deep and is harder than the inner core of material.

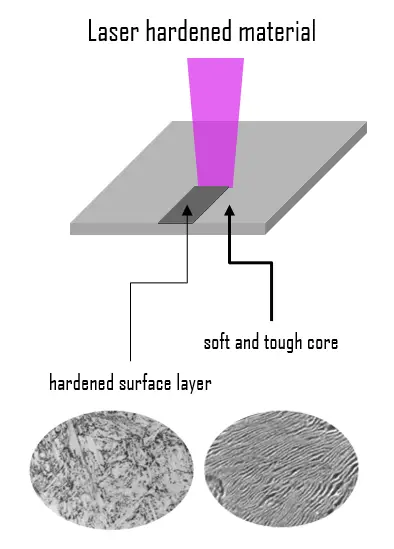

Laser Hardening

Laser hardening is a surface hardening technique which uses a laser beam to provide a very rapid means of heating the metal, which is then cooled rapidly (generally by self-quenching). This creates a “case” of martensite on the surface, while the inner core of the object remains elastic and tough. The heat generated by the absorption of the laser light is controlled to prevent melting and is therefore used in the selective austenitization of local surface regions. Self-quenching phenomenon applies after removing the heat source from the interaction zone. Thermal energy absorbed by surface layer is quickly distributed to the entire workpiece.

Laser hardening is a surface hardening technique which uses a laser beam to provide a very rapid means of heating the metal, which is then cooled rapidly (generally by self-quenching). This creates a “case” of martensite on the surface, while the inner core of the object remains elastic and tough. The heat generated by the absorption of the laser light is controlled to prevent melting and is therefore used in the selective austenitization of local surface regions. Self-quenching phenomenon applies after removing the heat source from the interaction zone. Thermal energy absorbed by surface layer is quickly distributed to the entire workpiece.

Martensite is a very hard metastable structure with a body-centered tetragonal (BCT) crystal structure. Martensite is formed in steels when the cooling rate from austenite is at such a high rate that carbon atoms do not have time to diffuse out of the crystal structure in large enough quantities to form cementite (Fe3C). Laser hardening produces hard, highly wear-resistant surface (shallow case depths). Thin surface zones that are heated and cooled very rapidly results in very fine martensitic micro-structures, even in steels with relatively low hardenability. Laser hardening is widely used to harden localized areas of steel and cast iron machine components. Main advantages are: possibility of selective surface heat treatment of complex parts, minimal deformations of processed parts, process is fast, clean and computer controlled.

Other Case Hardening Methods

Case hardening by surface treatment can be classified further as diffusion treatments or localized heating treatments. Diffusion methods introduce alloying elements that enter the surface by diffusion, either as solid-solution agents or as hardenability agents that assist martensite formation during subsequent quenching. In this process, the concentration of alloying element is increased at the surface of a steel component. Diffusion methods include:

- Carburizing. Carburizing is a case hardening process in which the surface carbon concentration of a ferrous alloy (usually a low-carbon steel) is increased by diffusion from the surrounding environment. Carburizing produces hard, highly wear-resistant surface (medium case depths) of product with excellent capacity for contact load, good bending fatigue strength and good resistance to seizure.

- Nitriding. Nitriding is a case hardening process in which the surface nitrogen concentration of a ferrous is increased by diffusion from the surrounding environment to create case-hardened surface. Nitriding produces hard, highly wear-resistant surface (shallow case depths) of product with fair capacity for contact load, good bending fatigue strength and excellent resistance to seizure.

- Boriding. Boriding, also called boronizing is a thermochemical diffusion process similar to nitrocarburising in which boron atoms diffuse into the substrate to produce hard and wear-resistant surface layers. The process requires a high treatment temperature (1073-1323 K) and long duration (1-12 h), and can be applied to a wide range of materials such as steels, cast iron, cermets, and non-ferrous alloys.

- Titanium-carbon and Titanium-nitride Hardening. Titanium nitride (an extremely hard ceramic material), or titanium carbide coatings can be used in the tools made of this kind of steels through physical vapor deposition process to improve the performance and life span of the tool. TiN has a Vickers hardness of 1800–2100 and it has metallic gold color.

Localized heating methods for case hardening include:

- Flame hardening. Flame hardening is a surface hardening technique which uses a single torch with a specially designed head to provide a very rapid means of heating the metal, which is then cooled rapidly, generally using water. This creates a “case” of martensite on the surface, while the inner core of the object remains elastic and tough. It is similar technique as induction hardening. A carbon content of 0.3–0.6 wt% C is needed for this type of hardening.

- Induction hardening. Induction hardening is a surface hardening technique which uses induction coils to provide a very rapid means of heating the metal, which is then cooled rapidly, generally using water. This creates a “case” of martensite on the surface. A carbon content of 0.3–0.6 wt% C is needed for this type of hardening.

- Laser hardening. Laser hardening is a surface hardening technique which uses a laser beam to provide a very rapid means of heating the metal, which is then cooled rapidly (generally by self-quenching). This creates a “case” of martensite on the surface, while the inner core of the object remains elastic and tough.

We hope, this article, Laser Hardening – Advantages and Application, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.