The term thermal annealing refers to a heat treatment in which a material is exposed to an elevated temperature for an extended time period and then slowly cooled. This process alters the physical and sometimes chemical properties of a material to increase its ductility and reduce its hardness, making it more workable. In this process, atoms migrate in the crystal lattice and the number of dislocations decreases, leading to a change in ductility and hardness. Metal gets rid of stresses and makes the grain structure large and soft-edged so that when the metal is hit or stressed it dents or perhaps bends, rather than breaking. Typically, annealing is carried out to relieve stresses, increase softness, ductility, and toughness; and/or produce a specific microstructure.

Generally, in plain carbon steels, annealing produces a ferrite-pearlite micro-structure. Steels may be annealed to facilitate cold working or machining, to improve mechanical or electrical properties, or to promote dimensional stability. The most common structural steels produced have a mixed ferrite-pearlite microstructure. Their applications include beams for bridges and high-rise buildings, plates for ships, and reinforcing bars for roadways. These steels are relatively inexpensive and are produced in large tonnages.

Any annealing cycle consists of three stages:

- heating to the desired temperature,

- holding or “soaking” at that temperature,

- cooling, usually to room temperature.

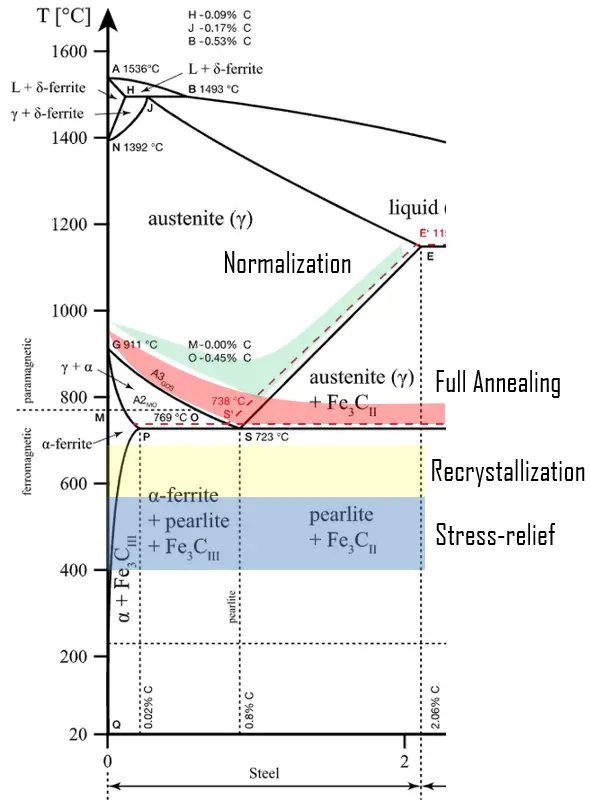

Time and annealing temperature are important parameters in these procedures. Especially the target temperature defines the annealing thermal cycle.

Stress-relief Annealing

Stress-relief annealing is used to relieve stresses from cold working. In contrast to process annealing, this heat treatment is usually performed after the product has been made. Care must be taken to ensure uniform cooling, particularly when a component is composed of variable section sizes. If the rate of cooling is not constant and uniform, new residual stresses can result that are equal to or greater than those that the heat-treating process was intended to relieve. The annealing temperature is typically a relatively low one such that effects resulting from cold working and other heat treatments are not affected. Stress-relief heat treating can reduce distortion and high stresses from welding that can affect service performance.

We hope, this article, Stress-relief Annealing, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.