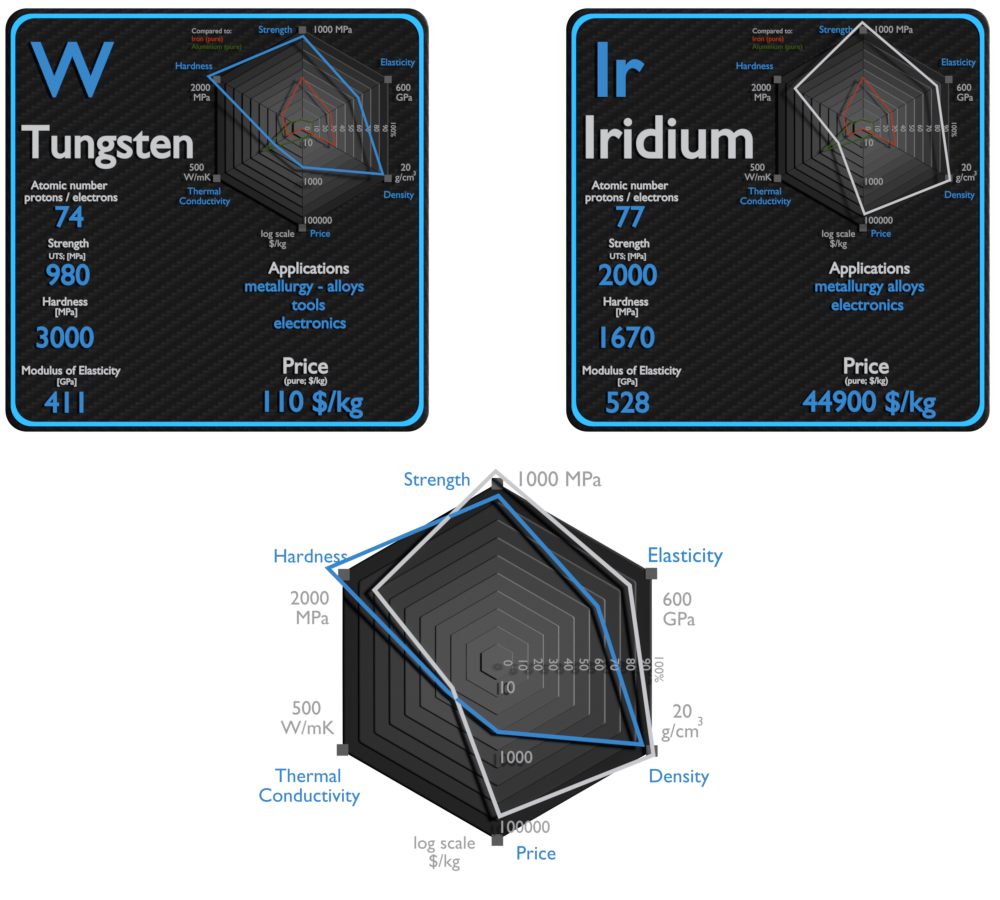

This article contains comparison of key thermal and atomic properties of tungsten and iridium, two comparable chemical elements from the periodic table. It also contains basic descriptions and applications of both elements. Tungsten vs Iridium.

Tugsten and Iridium – About Elements

Source: www.luciteria.com

Tungsten and Iridium – Applications

Tungsten

Tungsten is widely used metal. Approximately half of the tungsten is consumed for the production of hard materials – namely tungsten carbide – with the remaining major use being in alloys and steels. Mining and mineral processing demand wear-resistant machines and components, because the energies and masses of interacting bodies are significant. For this purposes, materials with the highest wear-resistance must be used. For example, tungsten carbide is used extensively in mining in top hammer rock drill bits, downhole hammers, roller-cutters, long wall plough chisels, long wall shearer picks, raiseboring reamers, and tunnel boring machines. The remaining 40% is generally used to make various alloys and specialty steels, electrodes, filaments, wires, as well as diverse components for electric, electronic, heating, lighting, and welding applications. High-speed steels are complex iron-base alloys of carbon, chromium, vanadium, molybdenum, or tungsten (as much as 18%), or combinations there of.

Iridium

Iridium is mainly consumed by the automotive, electronic, and chemical industries. Iridium metal is employed when high corrosion resistance at high temperatures is needed, as in high-performance spark plugs, crucibles for recrystallization of semiconductors at high temperatures, and electrodes for the production of chlorine in the chloralkali process. The demand for iridium surged from 2.5 tonnes in 2009 to 10.4 tonnes in 2010, mostly because of electronics-related applications that saw a rise from 0.2 to 6 tonnes – iridium crucibles are commonly used for growing large high-quality single crystals, demand for which has increased sharply.

Tungsten and Iridium – Comparison in Table

| Element | Tungsten | Iridium |

| Density | 19.25 g/cm3 | 22.65 g/cm3 |

| Ultimate Tensile Strength | 980 MPa | 2000 MPa |

| Yield Strength | 750 MPa | N/A |

| Young’s Modulus of Elasticity | 411 GPa | 528 GPa |

| Mohs Scale | 7.5 | 6.25 |

| Brinell Hardness | 3000 MPa | 1670 MPa |

| Vickers Hardness | 3500 MPa | 1760 MPa |

| Melting Point | 3410 °C | 2410 °C |

| Boiling Point | 59300 °C | 4130 °C |

| Thermal Conductivity | 170 W/mK | 150 W/mK |

| Thermal Expansion Coefficient | 4.5 µm/mK | 6.4 µm/mK |

| Specific Heat | 0.13 J/g K | 0.13 J/g K |

| Heat of Fusion | 35.4 kJ/mol | 26.1 kJ/mol |

| Heat of Vaporization | 824 kJ/mol | 604 kJ/mol |