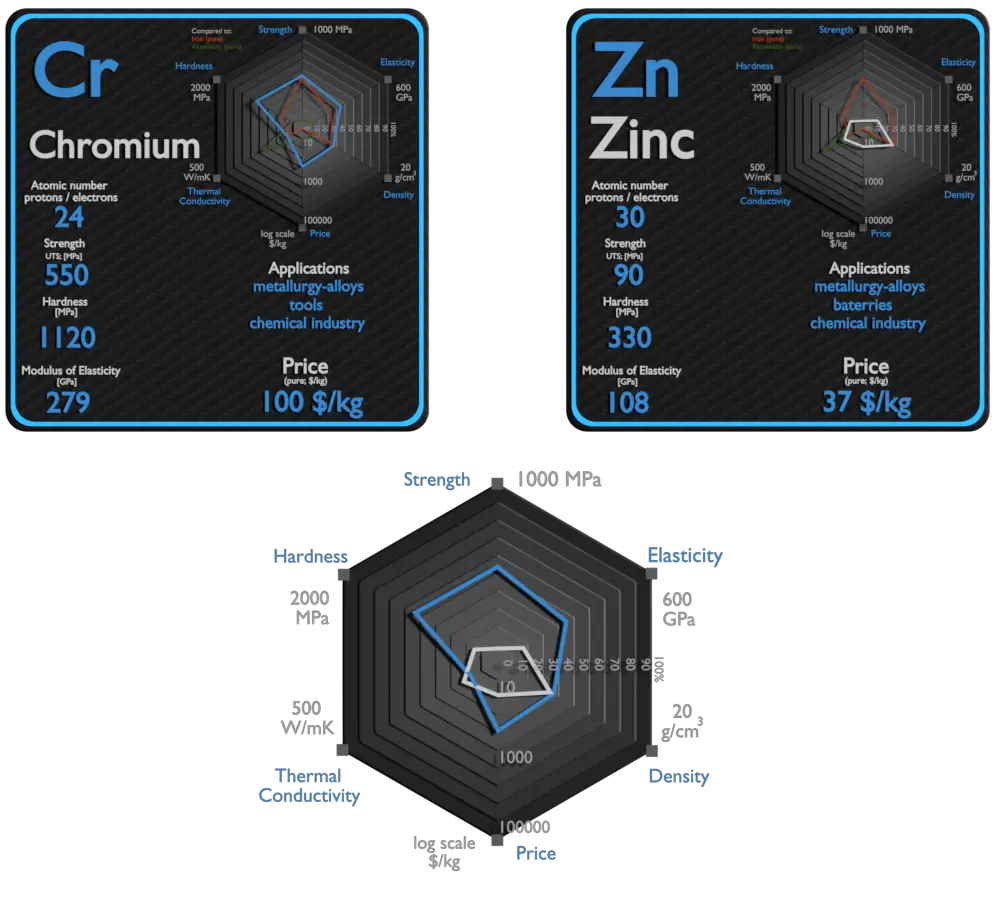

This article contains comparison of key thermal and atomic properties of chromium and zinc, two comparable chemical elements from the periodic table. It also contains basic descriptions and applications of both elements. Chromium vs Zinc.

Chromium and Zinc – About Elements

Source: www.luciteria.com

Chromium and Zinc – Applications

Chromium

Chromium is one of the most important and indispensable industrial metals because of its hardness and resistance to corrosion. But it is used for more than the production of stainless steel and nonferrous alloys; it is also used to create pigments and chemicals used to process leather. In metallurgy, Chromium increases hardness, strength, and corrosion resistance. The strengthening effect of forming stable metal carbides at the grain boundaries and the strong increase in corrosion resistance made chromium an important alloying material for steel. Generally speaking, the concentration specified for most grades is approximately 4%. This level appears to result in the best balance between hardness and toughness. Chromium plays an important role in the hardening mechanism and is considered irreplaceable. At higher temperatures, chromium contributes increased strength. It is ordinarily used for applications of this nature in conjunction with molybdenum. The resistance of stainless steels is based on passivation. For passivation to occur and remain stable, the Fe-Cr alloy must have a minimum chromium content of about 11% by weight, above which passivity can occur and below which it is impossible.

Zinc

Corrosion-resistant zinc plating of iron (hot-dip galvanizing) is the major application for zinc. Coating of steel constitutes the largest single use of zinc, but it is used in large tonnages in zinc alloy castings, as zinc dust and oxide, and in wrought zinc products. Galvanized steel is just plain carbon steel that has been coated with a thin zinc layer. The zinc protects iron by corroding first, but zinc corrodes at much lower rates than do steel. Other applications are in electrical batteries, small non-structural castings, and alloys such as brass. A variety of zinc compounds are commonly used, such as zinc carbonate and zinc gluconate (as dietary supplements), zinc chloride (in deodorants), zinc pyrithione (anti-dandruff shampoos), zinc sulfide (in luminescent paints), and dimethylzinc or diethylzinc in the organic laboratory. A key part of the modern materials world in which zinc finds itself is recycling. Zinc, in common with all metals (and unlike synthetic materials) can be recycled indefinitely without degradation.

Chromium and Zinc – Comparison in Table

| Element | Chromium | Zinc |

| Density | 7.14 g/cm3 | 7.14 g/cm3 |

| Ultimate Tensile Strength | 550 MPa | 90 MPa |

| Yield Strength | 131 MPa | 75 MPa |

| Young’s Modulus of Elasticity | 279 GPa | 108 GPa |

| Mohs Scale | 8.5 | 2.5 |

| Brinell Hardness | 1120 MPa | 330 MPa |

| Vickers Hardness | 1060 MPa | N/A |

| Melting Point | 1907 °C | 419.53 °C |

| Boiling Point | 2671 °C | 907 °C |

| Thermal Conductivity | 93.7 W/mK | 116 W/mK |

| Thermal Expansion Coefficient | 4.9 µm/mK | 30.2 µm/mK |

| Specific Heat | 0.45 J/g K | 0.39 J/g K |

| Heat of Fusion | 16.9 kJ/mol | 7.322 kJ/mol |

| Heat of Vaporization | 344.3 kJ/mol | 115.3 kJ/mol |