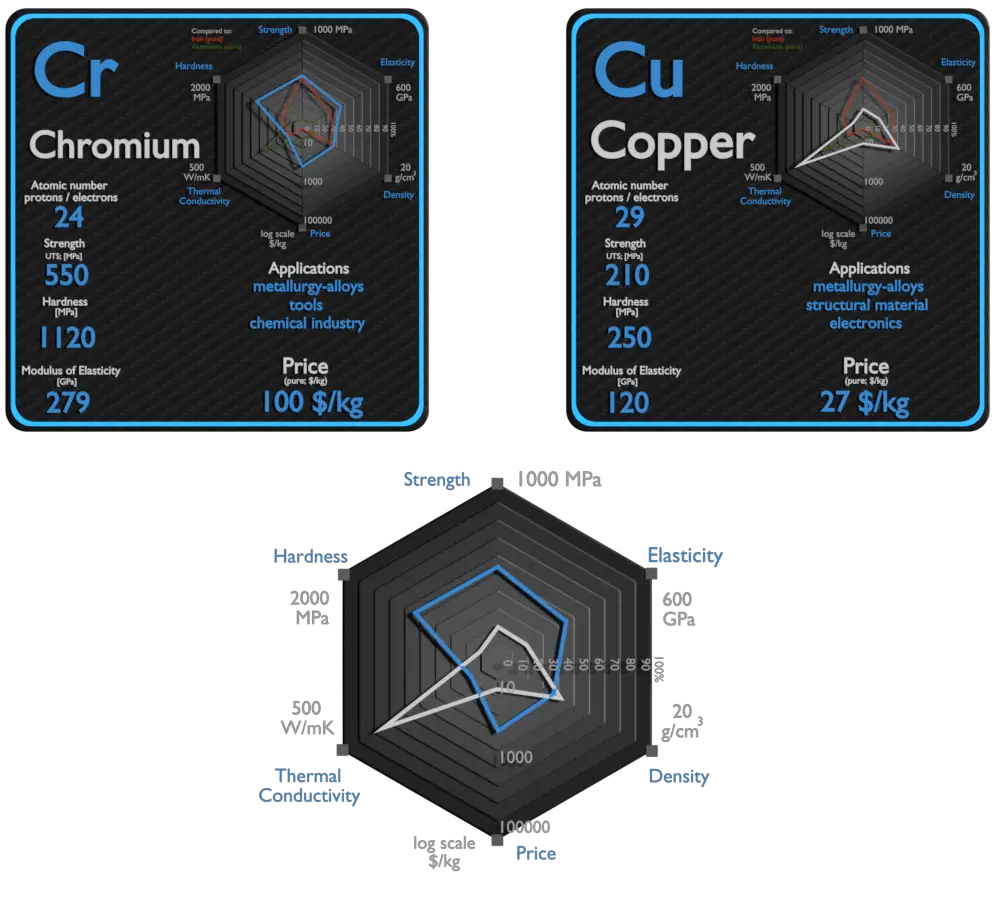

This article contains comparison of key thermal and atomic properties of chromium and copper, two comparable chemical elements from the periodic table. It also contains basic descriptions and applications of both elements. Chromium vs Copper.

Chromium and Copper – About Elements

Source: www.luciteria.com

Chromium and Copper – Applications

Chromium

Chromium is one of the most important and indispensable industrial metals because of its hardness and resistance to corrosion. But it is used for more than the production of stainless steel and nonferrous alloys; it is also used to create pigments and chemicals used to process leather. In metallurgy, Chromium increases hardness, strength, and corrosion resistance. The strengthening effect of forming stable metal carbides at the grain boundaries and the strong increase in corrosion resistance made chromium an important alloying material for steel. Generally speaking, the concentration specified for most grades is approximately 4%. This level appears to result in the best balance between hardness and toughness. Chromium plays an important role in the hardening mechanism and is considered irreplaceable. At higher temperatures, chromium contributes increased strength. It is ordinarily used for applications of this nature in conjunction with molybdenum. The resistance of stainless steels is based on passivation. For passivation to occur and remain stable, the Fe-Cr alloy must have a minimum chromium content of about 11% by weight, above which passivity can occur and below which it is impossible.

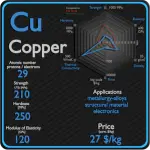

Copper

Historically, alloying copper with another metal, for example tin to make bronze, was first practiced about 4000 years after the discovery of copper smelting, and about 2000 years after “natural bronze” had come into general use. An ancient civilization is defined to be in the Bronze Age either by producing bronze by smelting its own copper and alloying with tin, arsenic, or other metals. The major applications of copper are electrical wire (60%), roofing and plumbing (20%), and industrial machinery (15%). Copper is used mostly as a pure metal, but when greater hardness is required, it is put into such alloys as brass and bronze (5% of total use). Copper and copper-based alloys including brasses (Cu-Zn) and bronzes (Cu-Sn) are widely used in different industrial and societal applications. Some of the common uses for brass alloys include costume jewelry, locks, hinges, gears, bearings, ammunition casings, automotive radiators, musical instruments, electronic packaging, and coins. Bronze, or bronze-like alloys and mixtures, were used for coins over a longer period. is still widely used today for springs, bearings, bushings, automobile transmission pilot bearings, and similar fittings, and is particularly common in the bearings of small electric motors. Brass and bronze are common engineering materials in modern architecture and primarily used for roofing and facade cladding due to their visual appearance.

Chromium and Copper – Comparison in Table

| Element | Chromium | Copper |

| Density | 7.14 g/cm3 | 8.92 g/cm3 |

| Ultimate Tensile Strength | 550 MPa | 210 MPa |

| Yield Strength | 131 MPa | 33 MPa |

| Young’s Modulus of Elasticity | 279 GPa | 120 GPa |

| Mohs Scale | 8.5 | 3 |

| Brinell Hardness | 1120 MPa | 250 MPa |

| Vickers Hardness | 1060 MPa | 350 MPa |

| Melting Point | 1907 °C | 1084.62 °C |

| Boiling Point | 2671 °C | 2562 °C |

| Thermal Conductivity | 93.7 W/mK | 401 W/mK |

| Thermal Expansion Coefficient | 4.9 µm/mK | 16.5 µm/mK |

| Specific Heat | 0.45 J/g K | 0.38 J/g K |

| Heat of Fusion | 16.9 kJ/mol | 13.05 kJ/mol |

| Heat of Vaporization | 344.3 kJ/mol | 300.3 kJ/mol |