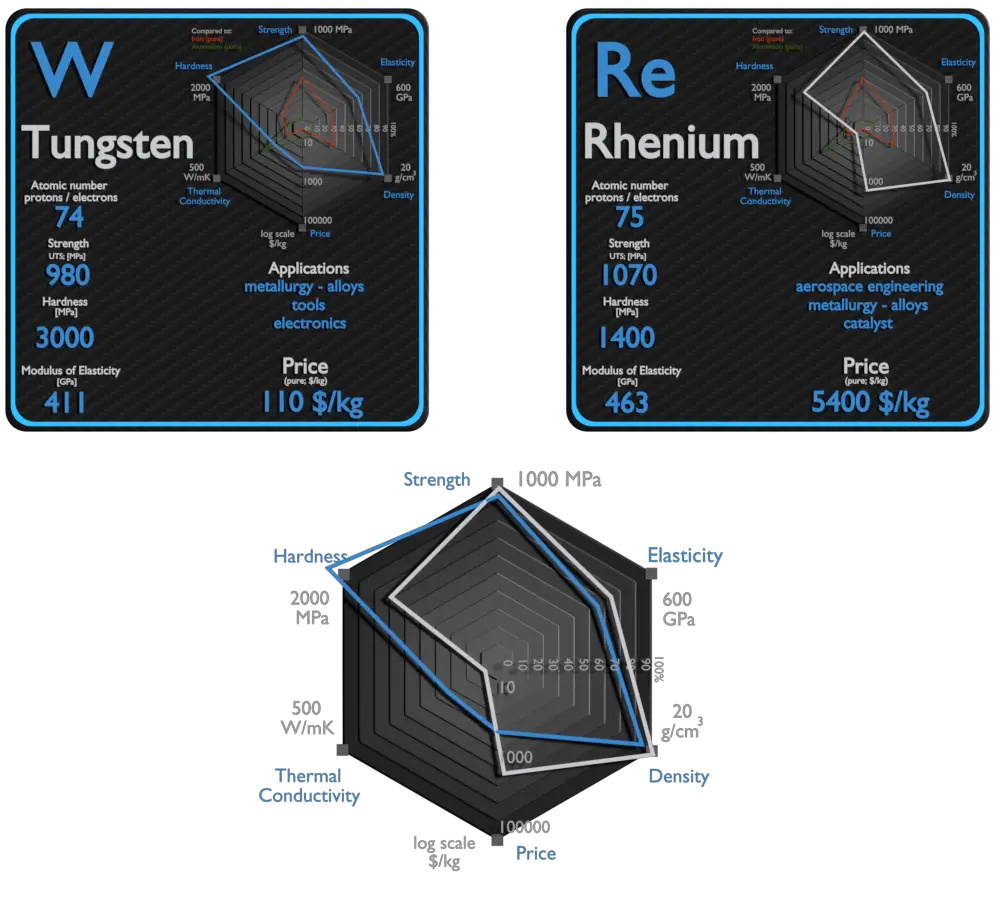

This article contains comparison of key thermal and atomic properties of tungsten and rhenium, two comparable chemical elements from the periodic table. It also contains basic descriptions and applications of both elements. Tungsten vs Rhenium.

Tugsten and Rhenium – About Elements

Source: www.luciteria.com

Tungsten and Rhenium – Applications

Tungsten

Tungsten is widely used metal. Approximately half of the tungsten is consumed for the production of hard materials – namely tungsten carbide – with the remaining major use being in alloys and steels. Mining and mineral processing demand wear-resistant machines and components, because the energies and masses of interacting bodies are significant. For this purposes, materials with the highest wear-resistance must be used. For example, tungsten carbide is used extensively in mining in top hammer rock drill bits, downhole hammers, roller-cutters, long wall plough chisels, long wall shearer picks, raiseboring reamers, and tunnel boring machines. The remaining 40% is generally used to make various alloys and specialty steels, electrodes, filaments, wires, as well as diverse components for electric, electronic, heating, lighting, and welding applications. High-speed steels are complex iron-base alloys of carbon, chromium, vanadium, molybdenum, or tungsten (as much as 18%), or combinations there of.

Rhenium

More than 80% of the global rhenium usage is in high-temperature superalloys for aircraft applications like turbine blades and engine parts. These alloys contain up to 6% rhenium, making jet engine construction the largest single use for the element. Rhenium is added to nickel-based super alloys to improve creep strength of the alloys. The remaining demand is mostly from petrochemical refining industries. Platinum-rhenium catalysts that are chiefly used in lead-free, high-octane gasoline are another major application of rhenium.

Tungsten and Rhenium – Comparison in Table

| Element | Tungsten | Rhenium |

| Density | 19.25 g/cm3 | 21.02 g/cm3 |

| Ultimate Tensile Strength | 980 MPa | 1070 MPa |

| Yield Strength | 750 MPa | 290 MPa |

| Young’s Modulus of Elasticity | 411 GPa | 463 GPa |

| Mohs Scale | 7.5 | 7 |

| Brinell Hardness | 3000 MPa | 1400 MPa |

| Vickers Hardness | 3500 MPa | 2500 MPa |

| Melting Point | 3410 °C | 3180 °C |

| Boiling Point | 59300 °C | 5600 °C |

| Thermal Conductivity | 170 W/mK | 48 W/mK |

| Thermal Expansion Coefficient | 4.5 µm/mK | 6.2 µm/mK |

| Specific Heat | 0.13 J/g K | 0.13 J/g K |

| Heat of Fusion | 35.4 kJ/mol | 33.2 kJ/mol |

| Heat of Vaporization | 824 kJ/mol | 715 kJ/mol |