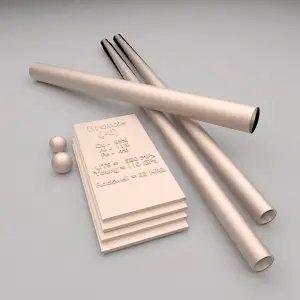

Corrosion-resistant alloys, as their name indicates, are alloys with enhanced corrosion resistance. Some ferrous and many non-ferrous metals and alloys are widely used in corrosive environments. In all cases, it strongly depends on certain environment and other conditions. Corrosion-resistant alloys are used for water piping and many chemical and industrial applications. In case of ferrous alloys, we are talking about stainless steels and to some extent about cast irons. But some non-ferrous corrosion-resistant alloys exhibit remarkable corrosion resistance nad therefore they may be used for many special purposes. There are two main reasons why nonferrous materials are preferred over steels and stainless steels for many of these applications. For example, many of the non-ferrous metals and alloys possess much higher resistance to corrosion than available alloy steels and stainless steel grades. Second, a high strength-to-weight ratio or high thermal and electrical conductivity may provide a distinct advantage over a ferrous alloy.

Corrosion-resistant alloys, as their name indicates, are alloys with enhanced corrosion resistance. Some ferrous and many non-ferrous metals and alloys are widely used in corrosive environments. In all cases, it strongly depends on certain environment and other conditions. Corrosion-resistant alloys are used for water piping and many chemical and industrial applications. In case of ferrous alloys, we are talking about stainless steels and to some extent about cast irons. But some non-ferrous corrosion-resistant alloys exhibit remarkable corrosion resistance nad therefore they may be used for many special purposes. There are two main reasons why nonferrous materials are preferred over steels and stainless steels for many of these applications. For example, many of the non-ferrous metals and alloys possess much higher resistance to corrosion than available alloy steels and stainless steel grades. Second, a high strength-to-weight ratio or high thermal and electrical conductivity may provide a distinct advantage over a ferrous alloy.

Uses of Corrosion-resistant Alloys – Application

Four common non-ferrous metals used for their well-documented corrosion resistance properties are:

-

Nibral Propeller (nickel aluminium bronze) Source: generalpropeller.com Copper. Copper does not react with water, but it does slowly react with atmospheric oxygen to form a layer of brown-black copper oxide which, unlike the rust that forms on iron in moist air, protects the underlying metal from further corrosion (passivation). Copper nickel alloys and aluminium bronze demonstrate superior resistance to saltwater corrosion. For example, cupronickels are copper-nickel alloys that contain typically from 60 to 90 percent of copper and nickel as the main alloying element. The two main alloys are 90/10 and 70/30. Other strengthening elements, such as manganese and iron, may be also contained. Cupronickels have excellent resistance to corrosion caused by sea water. Despite its high copper content, cupronickel is silver in colour. The addition of nickel to copper also improves strength and corrosion resistance, but good ductility is retained. Cupronickels may be used in many marine applications, such as for the propellers and propeller shafts. Since cupronickel alloys have inherent resistance to macrofouling, good tensile strength, excellent ductility when annealed, high thermal conductivity and expansion characteristics, they may be used for heat exchangers, such as in steam turbine condensers, oil coolers, auxiliary cooling systems and high pressure pre-heaters at nuclear and fossil fuel power plants. Another very common corrosion-resistant material is an aluminium bronze, which has excellent corrosion resistance especially in seawater and similar environments, where the alloys often outperform many stainless steels. Their excellent resistance to corrosion results from the aluminium in the alloys, which reacts with atmospheric oxygen to form a thin, tough surface layer of alumina (aluminium oxide) which acts as a barrier to corrosion of the copper-rich alloy. They are found in wrought and cast form. Aluminium bronzes are usually golden in color. Aluminium bronzes are used in sea water applications that include:

- General sea water-related services

- Bearings

- Pipe fittings

- Pumps and valve components

- Heat exchangers

Nickel. Nickel is a silvery-white lustrous metal with a slight golden tinge. Nickel is one of most common alloying elements. About 65% of nickel production is used in stainless steels. Because nickel does not form any carbide compounds in steel, it remains in solution in the ferrite, thus strengthening and toughening the ferrite phase. Nickel steels are easily heat treated because nickel lowers the critical cooling rate. Nickel based alloys (e.g. Fe-Cr-Ni(Mo) alloys) alloys exhibit excellent ductility and toughness, even at high strength levels and these properties are retained up to low temperatures. Nickel and its alloys are highly resistant to corrosion in many environments, especially those that are basic (alkaline). Nickel also reduces thermal expansion for better dimensional stability. Nickel is the base elements for superalloys. These metals have excellent resistance to thermal creep deformation and retain their stiffness, strength, toughness and dimensional stability at temperatures much higher than the other aerospace structural materials. For example, Inconel is a registered trademark of Special Metals for a family of austenitic nickel-chromium-based superalloys. Inconel 718 is a nickel-based superalloy that possesses high strength properties and resistance to elevated temperatures. It also demonstrates remarkable protection against corrosion and oxidation. They were initially developed for use in aircraft piston engine turbosuperchargers. Today, the most common application is in aircraft turbine components, which must withstand exposure to severely oxidizing environments and high temperatures for reasonable time periods.

Nickel. Nickel is a silvery-white lustrous metal with a slight golden tinge. Nickel is one of most common alloying elements. About 65% of nickel production is used in stainless steels. Because nickel does not form any carbide compounds in steel, it remains in solution in the ferrite, thus strengthening and toughening the ferrite phase. Nickel steels are easily heat treated because nickel lowers the critical cooling rate. Nickel based alloys (e.g. Fe-Cr-Ni(Mo) alloys) alloys exhibit excellent ductility and toughness, even at high strength levels and these properties are retained up to low temperatures. Nickel and its alloys are highly resistant to corrosion in many environments, especially those that are basic (alkaline). Nickel also reduces thermal expansion for better dimensional stability. Nickel is the base elements for superalloys. These metals have excellent resistance to thermal creep deformation and retain their stiffness, strength, toughness and dimensional stability at temperatures much higher than the other aerospace structural materials. For example, Inconel is a registered trademark of Special Metals for a family of austenitic nickel-chromium-based superalloys. Inconel 718 is a nickel-based superalloy that possesses high strength properties and resistance to elevated temperatures. It also demonstrates remarkable protection against corrosion and oxidation. They were initially developed for use in aircraft piston engine turbosuperchargers. Today, the most common application is in aircraft turbine components, which must withstand exposure to severely oxidizing environments and high temperatures for reasonable time periods.- Titanium. Pure titanium is stronger than common, low-carbon steels, but 45% lighter. It is also twice as strong as weak aluminium alloys but only 60% heavier. The two most useful properties of the metal are corrosion resistance and strength-to-density ratio, the highest of any metallic element. The corrosion resistance of titanium alloys at normal temperatures is unusually high. Titanium’s corrosion resistance is based on the formation of a stable, protective oxide layer. Although “commercially pure” titanium has acceptable mechanical properties and has been used for orthopedic and dental implants, for most applications titanium is alloyed with small amounts of aluminium and vanadium, typically 6% and 4% respectively, by weight. This mixture has a solid solubility which varies dramatically with temperature, allowing it to undergo precipitation strengthening. Titanium alloys are metals that contain a mixture of titanium and other chemical elements. Such alloys have very high tensile strength and toughness (even at extreme temperatures). They are light in weight, have extraordinary corrosion resistance and the ability to withstand extreme temperatures. For example, commercially pure titanium grade 2 is very similar to grade 1, but it has higher strength than grade 1 and excellent cold forming properties. It provides excellent welding properties and has excellent resistance to oxidation and corrosion. This grade of titanium is the most common grade of the commercially pure titanium industry. It is the prime choice for many fields of applications:

- Aerospace,

- Automotive,

- Chemical Processing & Chlorate Manufacturing,

- Desalination

- Power generation

- Aluminium. In general, aluminium alloys are characterized by a relatively low density (2.7 g/cm3 as compared to 7.9 g/cm3 for steel), high electrical and thermal conductivities, and a resistance to corrosion in some common environments, including the ambient atmosphere. Its corrosion resitance strongly depends on certain alloy. For example, duralumin is due to presence of copper susceptible to corrosion, while 6061 alloy remains resistant to corrosion even when the surface is abraded. At higher temperature and in aggressive environments, aluminium alloys have poor corrosion resistance and they also suffer from stress corrosion cracking.

We hope, this article, Uses of Corrosion-resistant Alloys – Application, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.