Light alloys are used widely in aerospace, automotive, architectural, lithographic, packaging, electrical and electronic applications. They are the prime material of construction for the aircraft industry throughout most of its history. About 70% of commercial civil aircraft airframes are made from aluminium alloys, and without aluminium civil aviation would not be economically viable. One kilogram of metal saved in the design and construction of an aircraft can result in important weight savings construction costs and in total fuel requirements.

Other metals, such as steel and titanium, are sometimes used to build aircraft. Steel is heavy though, so not too much is used. Titanium is almost as strong as steel, has a medium weight, is heat resistant, and is corrosion resistant. For example, the Lockheed SR-71 Blackbird, the world’s fastest jet-propelled aircraft, is made of titanium. In some cases, these light alloys may be replaced by composite materials especially those made from glass fibers, carbon fibers, and Kevlar These composite materials are strong, but can weigh half as much as aluminium. These lightweight, customizable materials are becoming more popular. More than half of the materials used to make the Boeing 787 Dreamliner are composites.

Metal-based light alloys may be also used for parts that operate at high speeds and thus must be light weight to minimize inertial forces. Other commercial applications include hand-held tools, laptops, luggage, and ladders, automobiles (e.g., steering wheels and columns, seat frames, transmission cases).

Types of Light Alloys

As was written, magnesium, aluminium and titanium are light metals of significant commercial importance. These three metals and their alloys comprise the bulk of the high strength-to-weight ratio metallic materials used in industrial systems. Aluminium is the most versatile of these materials and titanium is the most corrosion resistant with very high strength, while magnesium has the lowest density. In addition to these metals, beryllium is also a high-strength, lightweight metal with very high elastic modulus (303 GPa) that is finding increasing use as a structural material in aerospace vehicles. The elastic modulus of beryllium is nearly three times that of titanium.

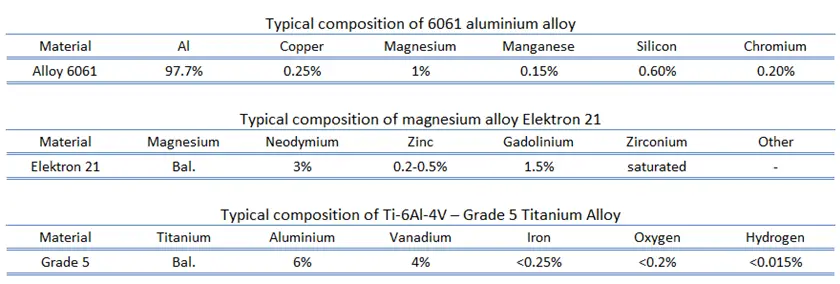

- Aluminium Alloys. Mechanical properties of aluminium alloys highly depend on their phase composition and microstructure. High strength can be achieved among others by introduction of a high volume fraction of fine, homogeneously distributed second phase particles and by a refinement of the grain size. In general, aluminium alloys are characterized by a relatively low density (2.7 g/cm3 as compared to 7.9 g/cm3 for steel), high electrical and thermal conductivities, and a resistance to corrosion in some common environments, including the ambient atmosphere. The chief limitation of aluminum is its low melting temperature (660°C), which restricts the maximum temperature at which it can be used. For general production the 5000 and 6000 series alloys provide adequate strength combined with good corrosion resistance, high toughness and ease of welding. Aluminium and its alloys are used widely in aerospace, automotive, architectural, lithographic, packaging, electrical and electronic applications.

- Magnesium Alloys. Magnesium alloys are mixtures of magnesium and other alloying metal, usually aluminium, zinc, silicon, manganese, copper and zirconium. Since the most outstanding characteristic of magnesium is its density, 1.7 g/cm3, its alloys are used where light weight is an important consideration (e.g., in aircraft components). Magnesium has the lowest melting (923 K (1,202 °F)) of all the alkaline earth metals. Magnesium alloys are typically used as cast alloys. Despite the reactive nature of the pure magnesium powder, magnesium metal and its alloys have good resistance to corrosion. We must add, pure magnesium is highly flammable, especially when powdered or shaved into thin strips, though it is difficult to ignite in mass or bulk. It produces intense, bright, white light when it burns. Flame temperatures of magnesium and some magnesium alloys can reach 3,100°C.

- Titanium Alloys. Titanium alloys are metals that contain a mixture of titanium and other chemical elements. Such alloys have very high tensile strength and toughness (even at extreme temperatures). They are light in weight, have extraordinary corrosion resistance and the ability to withstand extreme temperatures. Although “commercially pure” titanium has acceptable mechanical properties and has been used for orthopedic and dental implants, for most applications titanium is alloyed with small amounts of aluminium and vanadium, typically 6% and 4% respectively, by weight. This mixture has a solid solubility which varies dramatically with temperature, allowing it to undergo precipitation strengthening.

Density of Light Metals and Alloys

Density of typical aluminium alloy is 2.7 g/cm3 (6061 alloy).

Density of typical magnesium alloy is 1.8 g/cm3 (Elektron 21).

Density of typical titanium alloy is 4.43 g/cm3 (Ti-6Al-4V).

Strength of Light Metals and Alloys

In mechanics of materials, the strength of a material is its ability to withstand an applied load without failure or plastic deformation. Strength of materials basically considers the relationship between the external loads applied to a material and the resulting deformation or change in material dimensions. Strength of a material is its ability to withstand this applied load without failure or plastic deformation.

Ultimate Tensile Strength

Ultimate tensile strength of 6061 aluminium alloy depends greatly on the temper of the material, but for T6 temper it is about 290 MPa.

Ultimate tensile strength of Elektron 21 – UNS M12310 is about 280 MPa.

Ultimate tensile strength of Ti-6Al-4V – Grade 5 titanium alloy is about 1170 MPa.

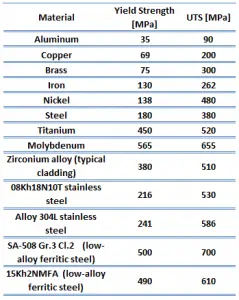

The ultimate tensile strength is the maximum on the engineering stress-strain curve. This corresponds to the maximum stress that can be sustained by a structure in tension. Ultimate tensile strength is often shortened to “tensile strength” or even to “the ultimate.” If this stress is applied and maintained, fracture will result. Often, this value is significantly more than the yield stress (as much as 50 to 60 percent more than the yield for some types of metals). When a ductile material reaches its ultimate strength, it experiences necking where the cross-sectional area reduces locally. The stress-strain curve contains no higher stress than the ultimate strength. Even though deformations can continue to increase, the stress usually decreases after the ultimate strength has been achieved. It is an intensive property; therefore its value does not depend on the size of the test specimen. However, it is dependent on other factors, such as the preparation of the specimen, the presence or otherwise of surface defects, and the temperature of the test environment and material. Ultimate tensile strengths vary from 50 MPa for an aluminum to as high as 3000 MPa for very high-strength steels.

The ultimate tensile strength is the maximum on the engineering stress-strain curve. This corresponds to the maximum stress that can be sustained by a structure in tension. Ultimate tensile strength is often shortened to “tensile strength” or even to “the ultimate.” If this stress is applied and maintained, fracture will result. Often, this value is significantly more than the yield stress (as much as 50 to 60 percent more than the yield for some types of metals). When a ductile material reaches its ultimate strength, it experiences necking where the cross-sectional area reduces locally. The stress-strain curve contains no higher stress than the ultimate strength. Even though deformations can continue to increase, the stress usually decreases after the ultimate strength has been achieved. It is an intensive property; therefore its value does not depend on the size of the test specimen. However, it is dependent on other factors, such as the preparation of the specimen, the presence or otherwise of surface defects, and the temperature of the test environment and material. Ultimate tensile strengths vary from 50 MPa for an aluminum to as high as 3000 MPa for very high-strength steels.

Yield Strength

Yield strength of 6061 aluminium alloy depends greatly on the temper of the material, but for T6 temper it is about 240 MPa.

Yield strength of Elektron 21 – UNS M12310 is about 145 MPa.

Yield strength of Ti-6Al-4V – Grade 5 titanium alloy is about 1100 MPa.

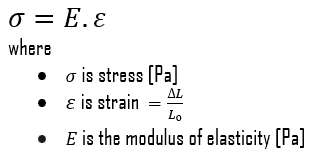

The yield point is the point on a stress-strain curve that indicates the limit of elastic behavior and the beginning plastic behavior. Yield strength or yield stress is the material property defined as the stress at which a material begins to deform plastically whereas yield point is the point where nonlinear (elastic + plastic) deformation begins. Prior to the yield point, the material will deform elastically and will return to its original shape when the applied stress is removed. Once the yield point is passed, some fraction of the deformation will be permanent and non-reversible. Some steels and other materials exhibit a behaviour termed a yield point phenomenon. Yield strengths vary from 35 MPa for a low-strength aluminum to greater than 1400 MPa for very high-strength steels.

Young’s Modulus of Elasticity

Young’s modulus of elasticity of 6061 aluminium alloy is about 69 GPa.

Young’s modulus of elasticity of Elektron 21 – UNS M12310 is about 45 GPa.

Young’s modulus of elasticity of Ti-6Al-4V – Grade 5 titanium alloy is about 114 GPa.

The Young’s modulus of elasticity is the elastic modulus for tensile and compressive stress in the linear elasticity regime of a uniaxial deformation and is usually assessed by tensile tests. Up to a limiting stress, a body will be able to recover its dimensions on removal of the load. The applied stresses cause the atoms in a crystal to move from their equilibrium position. All the atoms are displaced the same amount and still maintain their relative geometry. When the stresses are removed, all the atoms return to their original positions and no permanent deformation occurs. According to the Hooke’s law, the stress is proportional to the strain (in the elastic region), and the slope is Young’s modulus. Young’s modulus is equal to the longitudinal stress divided by the strain.

We hope, this article, What Materials Are Aircrafts Made Of – Light Alloys, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about materials and their properties.