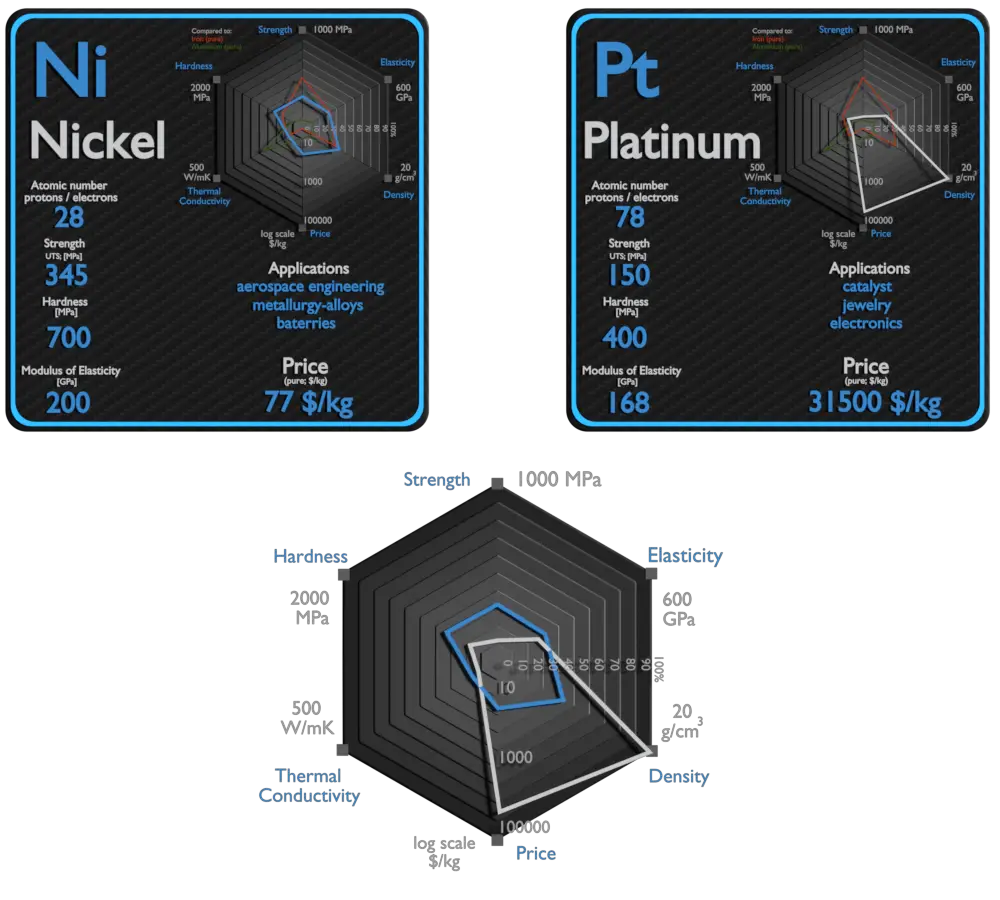

This article contains comparison of key thermal and atomic properties of nickel and platinum, two comparable chemical elements from the periodic table. It also contains basic descriptions and applications of both elements. Nickel vs Platinum.

Nickel and Platinum – About Elements

Source: www.luciteria.com

Nickel and Platinum – Applications

Nickel

The global production of nickel is presently used as follows: 68% in stainless steel; 10% in nonferrous alloys; 9% in electroplating; 7% in alloy steel; 3% in foundries; and 4% other uses (including batteries). Nickel is used as a constituent of different types of alloys; for instance, Monel (corrosion resistant material), Nichrome (an alloy used for resistance heating elements), Permalloy (an alloy with high magnetic permeability at low field strength and low hysteresis loss), cupro-nickel, stainless steel, nickel silver, etc. Nickel based alloys (e.g. Fe-Cr-Ni(Mo) alloys) alloys exhibit excellent ductility and toughness, even at high strength levels and these properties are retained up to low temperatures. Nickel and its alloys are highly resistant to corrosion in many environments, especially those that are basic (alkaline). Nickel also reduces thermal expansion for better dimensional stability. Nickel is the base element for superalloys. These metals have excellent resistance to thermal creep deformation and retain their stiffness, strength, toughness and dimensional stability at temperatures much higher than the other aerospace structural materials.

Platinum

Platinum is primarily an industrial metal. It is a critical material for many industries and is considered a strategic metal. Platinum is used as a catalyst, platinum is mostly found in vehicle catalytic converters that reduce toxic exhaust chemicals, and also in fuel cells to increase efficiency. The most common use of platinum is as a catalyst in chemical reactions, often as platinum black. In catalytic converters, platinum allows the complete combustion of low concentrations of unburned hydrocarbons from the exhaust into carbon dioxide and water vapor. Platinum has been used in thermocouple devices that measure temperature with high accuracy. Platinum is a component in magnetic coatings for high-density hard disk drives and some of the newer optical storage systems.

Nickel and Platinum – Comparison in Table

| Element | Nickel | Platinum |

| Density | 8.908 g/cm3 | 21.09 g/cm3 |

| Ultimate Tensile Strength | 345 MPa | 150 MPa |

| Yield Strength | 700 MPa | 70 MPa |

| Young’s Modulus of Elasticity | 200 GPa | 168 GPa |

| Mohs Scale | 4 | 3.5 |

| Brinell Hardness | 700 MPa | 400 MPa |

| Vickers Hardness | 640 MPa | 550 MPa |

| Melting Point | 1455 °C | 1772 °C |

| Boiling Point | 2730 °C | 3827 °C |

| Thermal Conductivity | 90.7 W/mK | 72 W/mK |

| Thermal Expansion Coefficient | 13.4 µm/mK | 8.8 µm/mK |

| Specific Heat | 0.44 J/g K | 0.13 J/g K |

| Heat of Fusion | 17.47 kJ/mol | 19.6 kJ/mol |

| Heat of Vaporization | 370.4 kJ/mol | 510 kJ/mol |