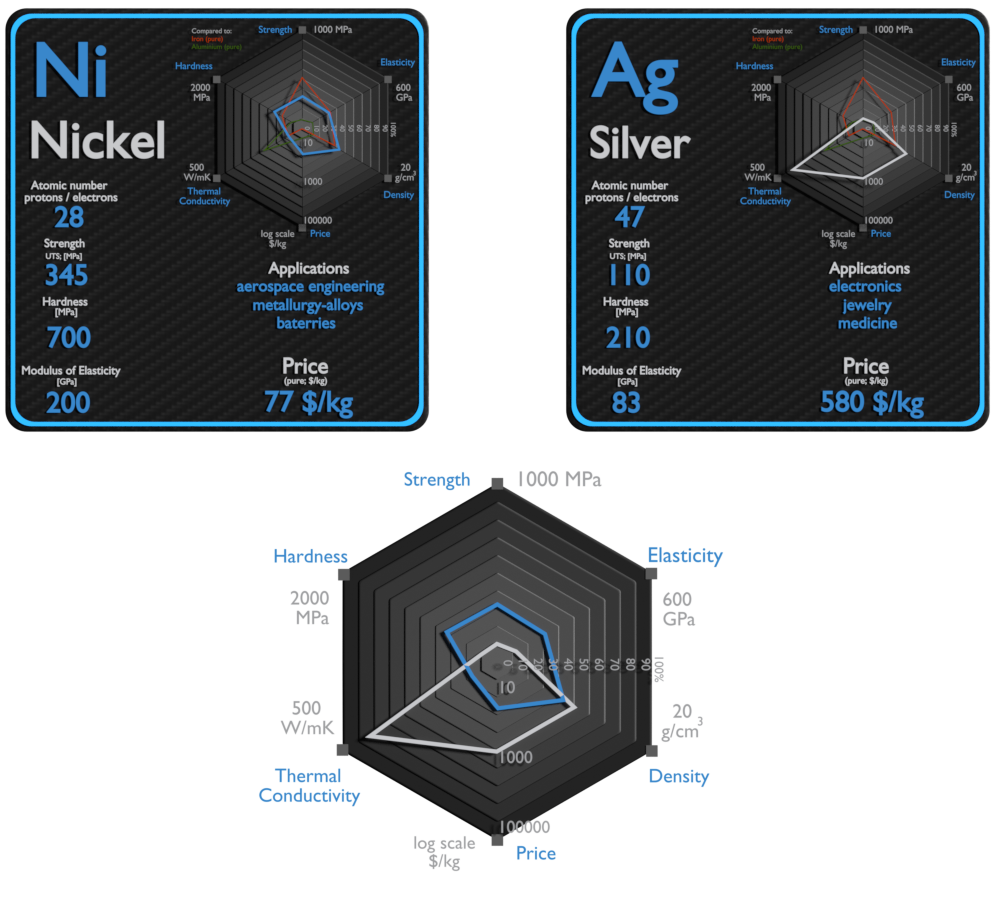

This article contains comparison of key thermal and atomic properties of nickel and silver, two comparable chemical elements from the periodic table. It also contains basic descriptions and applications of both elements. Nickel vs Silver.

Nickel and Silver – About Elements

Source: www.luciteria.com

Nickel and Silver – Applications

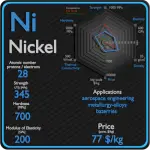

Nickel

The global production of nickel is presently used as follows: 68% in stainless steel; 10% in nonferrous alloys; 9% in electroplating; 7% in alloy steel; 3% in foundries; and 4% other uses (including batteries). Nickel is used as a constituent of different types of alloys; for instance, Monel (corrosion resistant material), Nichrome (an alloy used for resistance heating elements), Permalloy (an alloy with high magnetic permeability at low field strength and low hysteresis loss), cupro-nickel, stainless steel, nickel silver, etc. Nickel based alloys (e.g. Fe-Cr-Ni(Mo) alloys) alloys exhibit excellent ductility and toughness, even at high strength levels and these properties are retained up to low temperatures. Nickel and its alloys are highly resistant to corrosion in many environments, especially those that are basic (alkaline). Nickel also reduces thermal expansion for better dimensional stability. Nickel is the base element for superalloys. These metals have excellent resistance to thermal creep deformation and retain their stiffness, strength, toughness and dimensional stability at temperatures much higher than the other aerospace structural materials.

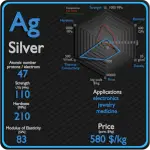

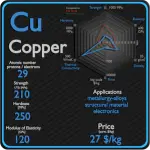

Silver

Silver has long been valued as a precious metal. Silver metal is used in many bullion coins, sometimes alongside gold. Silver has many important, far-reaching technological and electronic applications. It’s used in everything from cell phones, computers and semiconductors to automobiles, water-purification systems and—because it is the best conductor of heat of all elements—spacecraft solar radiation tiles. Silver is of the upmost importance in photography (where approximately 30% of the U.S. Industrial consumption goes into this application). The medical uses of silver include its use in wound dressings, creams, and as an antibiotic coating on medical devices. Wound dressings containing silver sulfadiazine or silver nanomaterials may be used on external infections.

Nickel and Silver – Comparison in Table

| Element | Nickel | Silver |

| Density | 8.908 g/cm3 | 10.49 g/cm3 |

| Ultimate Tensile Strength | 345 MPa | 110 MPa |

| Yield Strength | 700 MPa | 45 MPa |

| Young’s Modulus of Elasticity | 200 GPa | 83 GPa |

| Mohs Scale | 4 | 3.25 |

| Brinell Hardness | 700 MPa | 210 MPa |

| Vickers Hardness | 640 MPa | 251 MPa |

| Melting Point | 1455 °C | 961.78 °C |

| Boiling Point | 2730 °C | 2162 °C |

| Thermal Conductivity | 90.7 W/mK | 430 W/mK |

| Thermal Expansion Coefficient | 13.4 µm/mK | 18.9 µm/mK |

| Specific Heat | 0.44 J/g K | 0.235 J/g K |

| Heat of Fusion | 17.47 kJ/mol | 11.3 kJ/mol |

| Heat of Vaporization | 370.4 kJ/mol | 250.58 kJ/mol |