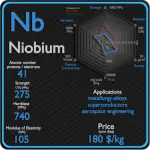

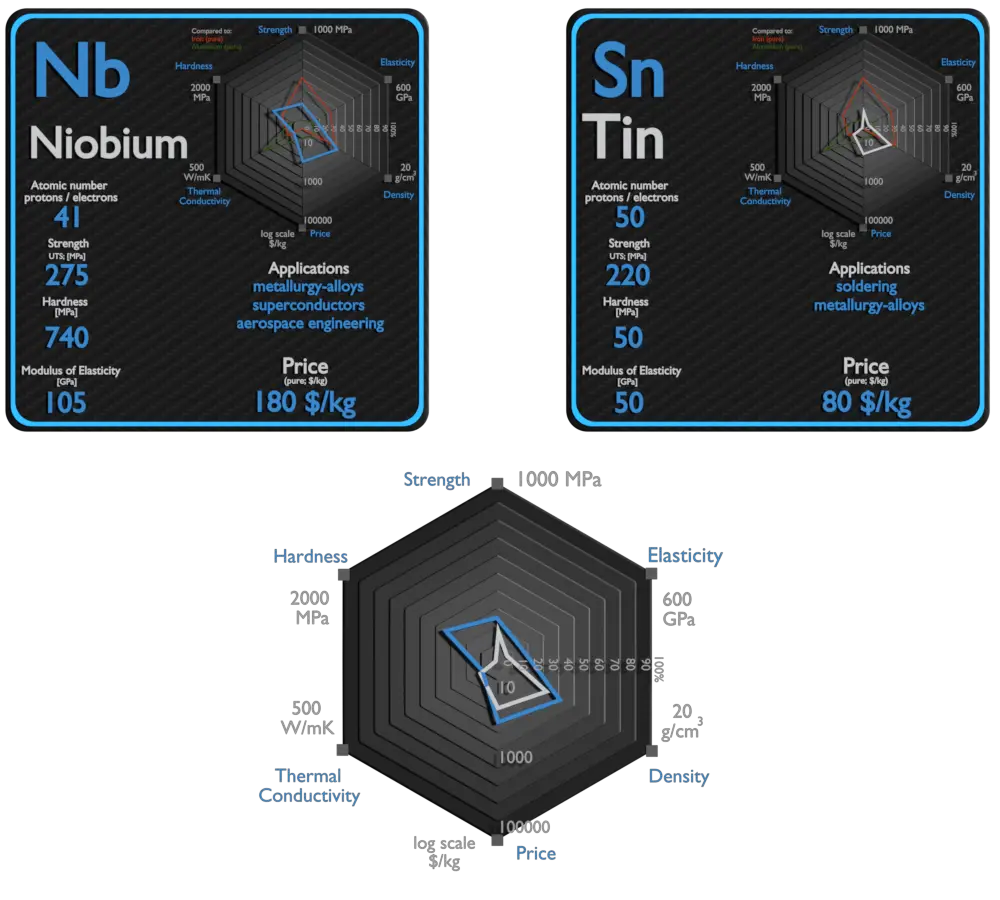

This article contains comparison of key thermal and atomic properties of niobium and tin, two comparable chemical elements from the periodic table. It also contains basic descriptions and applications of both elements. Niobium vs Tin.

Niobium and Tin – About Elements

Source: www.luciteria.com

Niobium and Tin – Applications

Niobium

Niobium consumption is dominated by its use as additive to high strength low alloy steel and stainless steel for oil and gas pipelines, car and truck bodies, architectural requirements, tool steels, ships hulls, railroad tracks. However, there are a number of other applications for niobium metal and its compounds. Although niobium has many applications the majority is used in the production of high-grade structural steel. The second largest application for niobium is in nickel-based superalloys. Niobium-tin alloys are used as superconducting magnets.

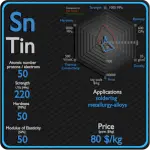

Tin

The largest single application of tin is in the manufacture of tinplate (steel sheet coated with tin), which accounts for approximately 40% of total world tin consumption. Tin bonds readily to iron and steel to prevent corrosion. Tin-plated steel containers are widely used for food preservation, and this forms a large part of the market for metallic tin. Tinning is the process of thinly coating sheets of wrought iron or steel with tin, and the resulting product is known as tinplate. The term is also widely used for the different process of coating a metal with solder before soldering. There are two processes for the tinning of the black plates: hot-dipping and electroplating.

Niobium and Tin – Comparison in Table

| Element | Niobium | Tin |

| Density | 8.57 g/cm3 | 7.31 g/cm3 |

| Ultimate Tensile Strength | 275 MPa | 220 MPa |

| Yield Strength | 70 MPa | N/A |

| Young’s Modulus of Elasticity | 105 GPa | 50 GPa |

| Mohs Scale | 6 | 1.65 |

| Brinell Hardness | 740 MPa | 50 MPa |

| Vickers Hardness | 1300 MPa | N/A |

| Melting Point | 2477 °C | 231.93 °C |

| Boiling Point | 4744 °C | 2602 °C |

| Thermal Conductivity | 53.7 W/mK | 67 W/mK |

| Thermal Expansion Coefficient | 7.3 µm/mK | 22 µm/mK |

| Specific Heat | 0.26 J/g K | 0.227 J/g K |

| Heat of Fusion | 26.4 kJ/mol | 7.029 kJ/mol |

| Heat of Vaporization | 682 kJ/mol | 295.8 kJ/mol |