About Glass

Glass is a non-crystalline, often transparent amorphous solid. Glasses have widespread practical, technological, and decorative use in, for example, window panes, tableware, and optics. Since glass is an amorphous (non-crystalline) solid, it is usually formed by the solidification of a melt without crystallisation. Glass is made by cooling molten ingredients such as silica sand with sufficient rapidity to prevent the formation of visible crystals. In some older books, the term has been used synonymously with glass. Nowadays, “glassy solid” or “amorphous solid” is considered to be the overarching concept, and glass the more special case: Glass is an amorphous solid that exhibits a glass transition. The glass you encounter most often is silicate glass, which consists mainly of silica or silicon dioxide, SiO2.

Summary

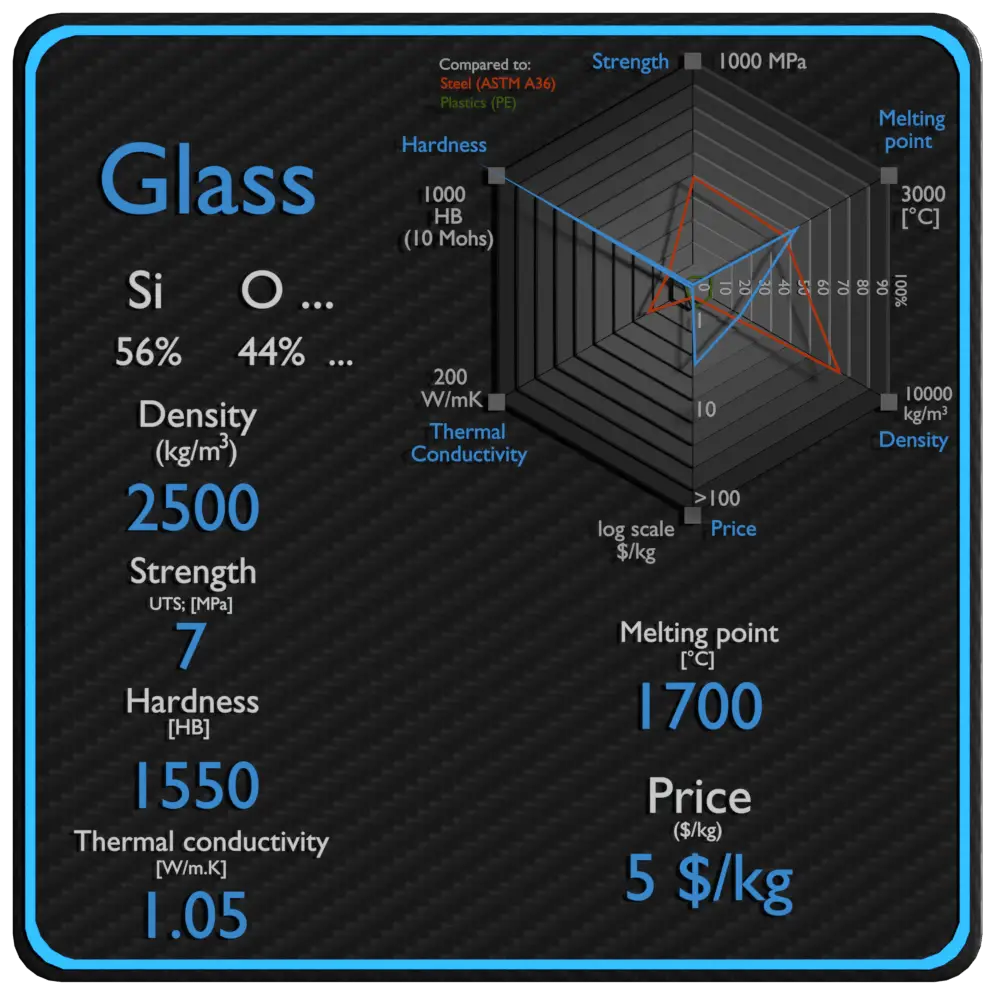

| Name | Glass |

| Phase at STP | solid |

| Density | 2500 kg/m3 |

| Ultimate Tensile Strength | 7 MPa |

| Yield Strength | N/A |

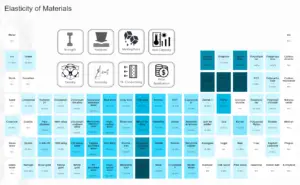

| Young’s Modulus of Elasticity | 80 GPa |

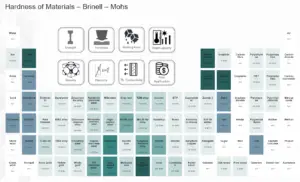

| Brinell Hardness | 1550 BHN |

| Melting Point | 1700 °C |

| Thermal Conductivity | 1.05 W/mK |

| Heat Capacity | 840 J/g K |

| Price | 5 $/kg |

Density of Glass

Typical densities of various substances are at atmospheric pressure. Density is defined as the mass per unit volume. It is an intensive property, which is mathematically defined as mass divided by volume: ρ = m/V

In words, the density (ρ) of a substance is the total mass (m) of that substance divided by the total volume (V) occupied by that substance. The standard SI unit is kilograms per cubic meter (kg/m3). The Standard English unit is pounds mass per cubic foot (lbm/ft3).

Density of Glass is 2500 kg/m3.

Example: Density

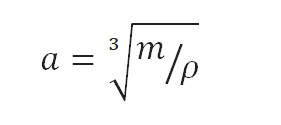

Calculate the height of a cube made of Glass, which weighs one metric ton.

Solution:

Density is defined as the mass per unit volume. It is mathematically defined as mass divided by volume: ρ = m/V

As the volume of a cube is the third power of its sides (V = a3), the height of this cube can be calculated:

The height of this cube is then a = 0.737 m.

Density of Materials

Mechanical Properties of Glass

Strength of Glass

In mechanics of materials, the strength of a material is its ability to withstand an applied load without failure or plastic deformation. Strength of materials basically considers the relationship between the external loads applied to a material and the resulting deformation or change in material dimensions. In designing structures and machines, it is important to consider these factors, in order that the material selected will have adequate strength to resist applied loads or forces and retain its original shape.

Strength of a material is its ability to withstand this applied load without failure or plastic deformation. For tensile stress, the capacity of a material or structure to withstand loads tending to elongate is known as ultimate tensile strength (UTS). Yield strength or yield stress is the material property defined as the stress at which a material begins to deform plastically whereas yield point is the point where nonlinear (elastic + plastic) deformation begins. In case of tensional stress of a uniform bar (stress-strain curve), the Hooke’s law describes behaviour of a bar in the elastic region. The Young’s modulus of elasticity is the elastic modulus for tensile and compressive stress in the linear elasticity regime of a uniaxial deformation and is usually assessed by tensile tests.

See also: Strength of Materials

Ultimate Tensile Strength of Glass

Ultimate tensile strength of Glass is 7 MPa.

Yield Strength of Glass

Yield strength of Glass is N/A.

Modulus of Elasticity of Glass

The Young’s modulus of elasticity of Glass is 80 MPa.

Hardness of Glass

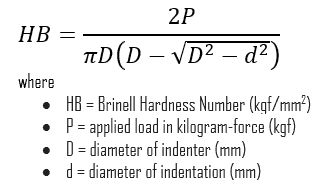

In materials science, hardness is the ability to withstand surface indentation (localized plastic deformation) and scratching. Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested.

The Brinell hardness number (HB) is the load divided by the surface area of the indentation. The diameter of the impression is measured with a microscope with a superimposed scale. The Brinell hardness number is computed from the equation:

Brinell hardness of Glass is approximately 1550 BHN (converted).

See also: Hardness of Materials

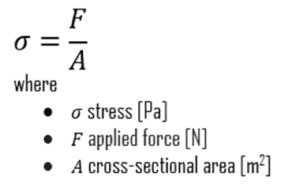

Example: Strength

Assume a plastic rod, which is made of Glass. This plastic rod has a cross-sectional area of 1 cm2. Calculate the tensile force needed to achieve the ultimate tensile strength for this material, which is: UTS = 7 MPa.

Solution:

Stress (σ) can be equated to the load per unit area or the force (F) applied per cross-sectional area (A) perpendicular to the force as:

therefore, the tensile force needed to achieve the ultimate tensile strength is:

F = UTS x A = 7 x 106 x 0.0001 = 700 N

Thermal Properties of Glass

Glass – Melting Point

Melting point of Glass is 1700 °C.

Note that, these points are associated with the standard atmospheric pressure. In general, melting is a phase change of a substance from the solid to the liquid phase. The melting point of a substance is the temperature at which this phase change occurs. The melting point also defines a condition in which the solid and liquid can exist in equilibrium. For various chemical compounds and alloys, it is difficult to define the melting point, since they are usually a mixture of various chemical elements.

Glass – Thermal Conductivity

Thermal conductivity of Glass is 1.05 W/(m·K).

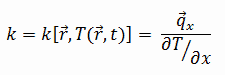

The heat transfer characteristics of a solid material are measured by a property called the thermal conductivity, k (or λ), measured in W/m.K. It is a measure of a substance’s ability to transfer heat through a material by conduction. Note that Fourier’s law applies for all matter, regardless of its state (solid, liquid, or gas), therefore, it is also defined for liquids and gases.

The thermal conductivity of most liquids and solids varies with temperature. For vapors, it also depends upon pressure. In general:

Most materials are very nearly homogeneous, therefore we can usually write k = k (T). Similar definitions are associated with thermal conductivities in the y- and z-directions (ky, kz), but for an isotropic material the thermal conductivity is independent of the direction of transfer, kx = ky = kz = k.

Glass – Specific Heat

Specific heat of Glass is 840 J/g K.

Specific heat, or specific heat capacity, is a property related to internal energy that is very important in thermodynamics. The intensive properties cv and cp are defined for pure, simple compressible substances as partial derivatives of the internal energy u(T, v) and enthalpy h(T, p), respectively:

where the subscripts v and p denote the variables held fixed during differentiation. The properties cv and cp are referred to as specific heats (or heat capacities) because under certain special conditions they relate the temperature change of a system to the amount of energy added by heat transfer. Their SI units are J/kg K or J/mol K.

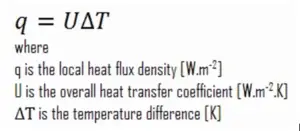

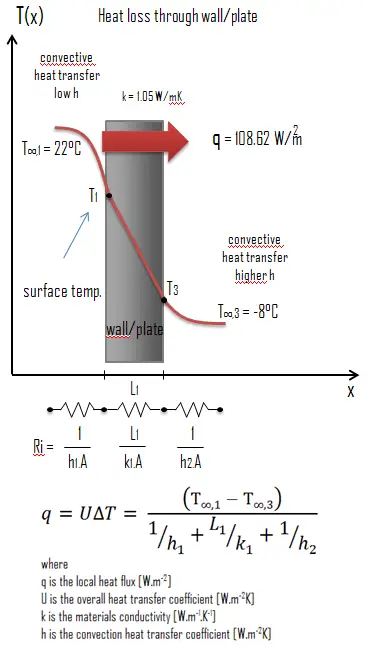

Example: Heat transfer calculation

Thermal conductivity is defined as the amount of heat (in watts) transferred through a square area of material of given thickness (in metres) due to a difference in temperature. The lower the thermal conductivity of the material the greater the material’s ability to resist heat transfer.

Thermal conductivity is defined as the amount of heat (in watts) transferred through a square area of material of given thickness (in metres) due to a difference in temperature. The lower the thermal conductivity of the material the greater the material’s ability to resist heat transfer.

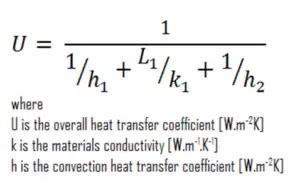

Calculate the rate of heat flux through a wall 3 m x 10 m in area (A = 30 m2). The wall is 15 cm thick (L1) and it is made of Glass with the thermal conductivity of k1 = 1.05 W/m.K (poor thermal insulator). Assume that, the indoor and the outdoor temperatures are 22°C and -8°C, and the convection heat transfer coefficients on the inner and the outer sides are h1 = 10 W/m2K and h2 = 30 W/m2K, respectively. Note that, these convection coefficients strongly depend especially on ambient and interior conditions (wind, humidity, etc.).

Calculate the heat flux (heat loss) through this wall.

Solution:

As was written, many of the heat transfer processes involve composite systems and even involve a combination of both conduction and convection. With these composite systems, it is often convenient to work with an overall heat transfer coefficient, known as a U-factor. The U-factor is defined by an expression analogous to Newton’s law of cooling:

The overall heat transfer coefficient is related to the total thermal resistance and depends on the geometry of the problem.

Assuming one-dimensional heat transfer through the plane wall and disregarding radiation, the overall heat transfer coefficient can be calculated as:

The overall heat transfer coefficient is then: U = 1 / (1/10 + 0.15/1.05 + 1/30) = 3.62 W/m2K

The heat flux can be then calculated simply as: q = 3.62 [W/m2K] x 30 [K] = 108.62 W/m2

The total heat loss through this wall will be: qloss = q . A = 108.62 [W/m2] x 30 [m2] = 3258.62 W