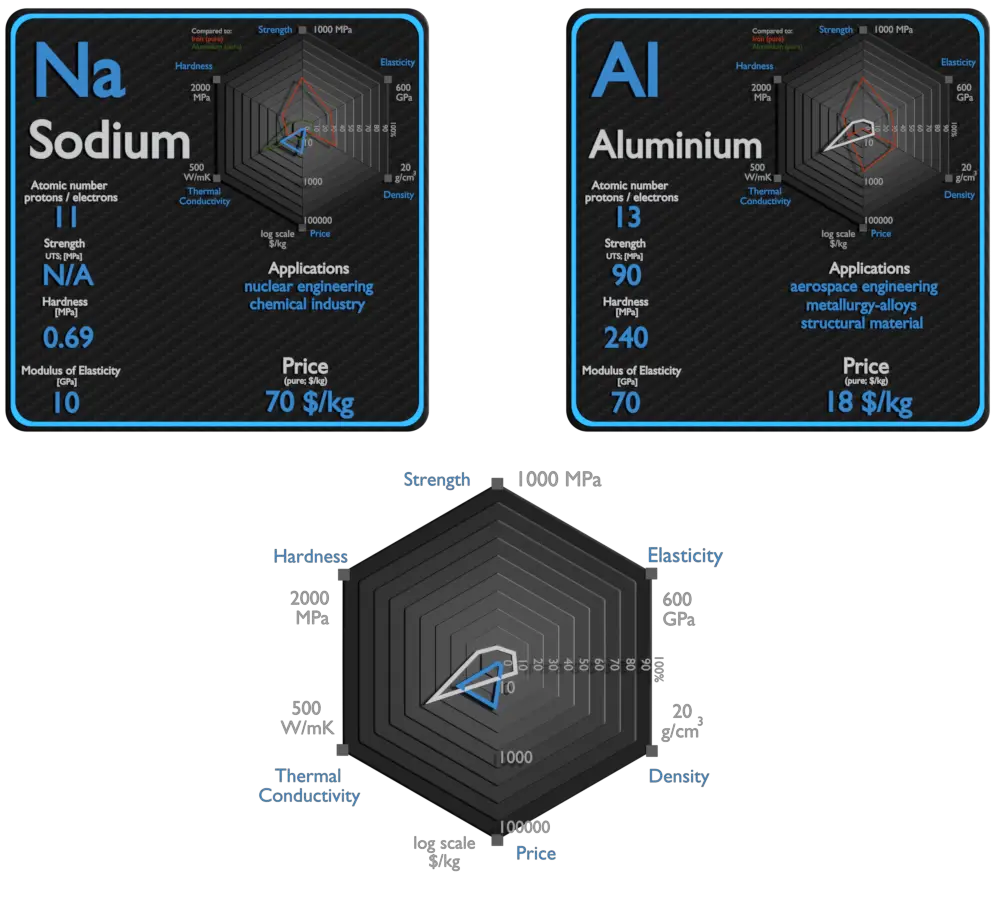

This article contains comparison of key thermal and atomic properties of sodium and aluminium, two comparable chemical elements from the periodic table. It also contains basic descriptions and applications of both elements. Sodium vs Aluminium.

Sodium and Aluminium – About Elements

Source: www.luciteria.com

Sodium and Aluminium – Applications

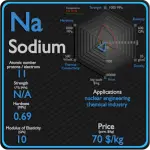

Sodium

Metallic sodium is used mainly for the production of sodium borohydride, sodium azide, indigo, and triphenylphosphine. A once-common use was the making of tetraethyllead and titanium metal; because of the move away from TEL and new titanium production methods. An electric current and sodium vapor combine to form a yellowish glow. This principle is used for the making of sodium vapor lamps. Sodium is occasionally used as a heat exchange medium in nuclear power plants. Liquid sodium is sealed into pipes surrounding the reactor core. Generated heat is absorbed by sodium and forced through the pipes in a heat exchanger which can be used to generate electricity.

Aluminium

Aluminium and its alloys are used widely in aerospace, automotive, architectural, lithographic, packaging, electrical and electronic applications. It is the prime material of construction for the aircraft industry throughout most of its history. About 70% of commercial civil aircraft airframes are made from aluminium alloys, and without aluminium civil aviation would not be economically viable. Automotive industry now includes aluminium as engine castings, wheels, radiators and increasingly as body parts. 6111 aluminium and 2008 aluminium alloy are extensively used for external automotive body panels. Cylinder blocks and crankcases are often cast made of aluminium alloys.

Sodium and Aluminium – Comparison in Table

| Element | Sodium | Aluminium |

| Density | 0.968 g/cm3 | 2.7 g/cm3 |

| Ultimate Tensile Strength | N/A | 90 MPa (pure), 600 MPa (alloys) |

| Yield Strength | N/A | 11 MPa (pure), 400 MPa (alloys) |

| Young’s Modulus of Elasticity | 10 GPa | 70 GPa |

| Mohs Scale | 0.4 | 2.8 |

| Brinell Hardness | 0.69 MPa | 240 MPa |

| Vickers Hardness | N/A | 167 MPa |

| Melting Point | 97.8 °C | 660 °C |

| Boiling Point | 883 °C | 2467 °C |

| Thermal Conductivity | 141 W/mK | 137 W/mK |

| Thermal Expansion Coefficient | 71 µm/mK | 23.1 µm/mK |

| Specific Heat | 1.23 J/g K | 0.9 J/g K |

| Heat of Fusion | 2.598 kJ/mol | 10.79 kJ/mol |

| Heat of Vaporization | 96.96 kJ/mol | 293.4 kJ/mol |