This article contains comparison of key thermal and atomic properties of oxygen and aluminium, two comparable chemical elements from the periodic table. It also contains basic descriptions and applications of both elements. Oxygen vs Aluminium.

Oxygen and Aluminium – About Elements

Source: www.luciteria.com

Oxygen and Aluminium – Applications

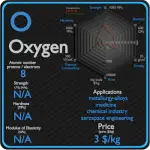

Oxygen

Common uses of oxygen include production of steel, plastics and textiles, brazing, welding and cutting of steels and other metals, rocket propellant, oxygen therapy, and life support systems in aircraft, submarines, spaceflight and diving. Smelting of iron ore into steel consumes 55% of commercially produced oxygen. In this process, oxygen is injected through a high-pressure lance into molten iron, which removes sulfur impurities and excess carbon as the respective oxides, sulfur dioxide and carbon dioxide. Uptake of oxygen from the air is the essential purpose of respiration, so oxygen supplementation is used in medicine. Treatment not only increases oxygen levels in the patient’s blood, but has the secondary effect of decreasing resistance to blood flow in many types of diseased lungs, easing work load on the heart.

Aluminium

Aluminium and its alloys are used widely in aerospace, automotive, architectural, lithographic, packaging, electrical and electronic applications. It is the prime material of construction for the aircraft industry throughout most of its history. About 70% of commercial civil aircraft airframes are made from aluminium alloys, and without aluminium civil aviation would not be economically viable. Automotive industry now includes aluminium as engine castings, wheels, radiators and increasingly as body parts. 6111 aluminium and 2008 aluminium alloy are extensively used for external automotive body panels. Cylinder blocks and crankcases are often cast made of aluminium alloys.

Oxygen and Aluminium – Comparison in Table

| Element | Oxygen | Aluminium |

| Density | 0.00125 g/cm3 | 2.7 g/cm3 |

| Ultimate Tensile Strength | N/A | 90 MPa (pure), 600 MPa (alloys) |

| Yield Strength | N/A | 11 MPa (pure), 400 MPa (alloys) |

| Young’s Modulus of Elasticity | N/A | 70 GPa |

| Mohs Scale | N/A | 2.8 |

| Brinell Hardness | N/A | 240 MPa |

| Vickers Hardness | N/A | 167 MPa |

| Melting Point | -209.9 °C | 660 °C |

| Boiling Point | -195.8 °C | 2467 °C |

| Thermal Conductivity | 0.02598 W/mK | 237 W/mK |

| Thermal Expansion Coefficient | N/A | 23.1 µm/mK |

| Specific Heat | 1.04 J/g K | 0.9 J/g K |

| Heat of Fusion | (N2) 0.7204 kJ/mol | 10.79 kJ/mol |

| Heat of Vaporization | (N2) 5.56 kJ/mol | 293.4 kJ/mol |