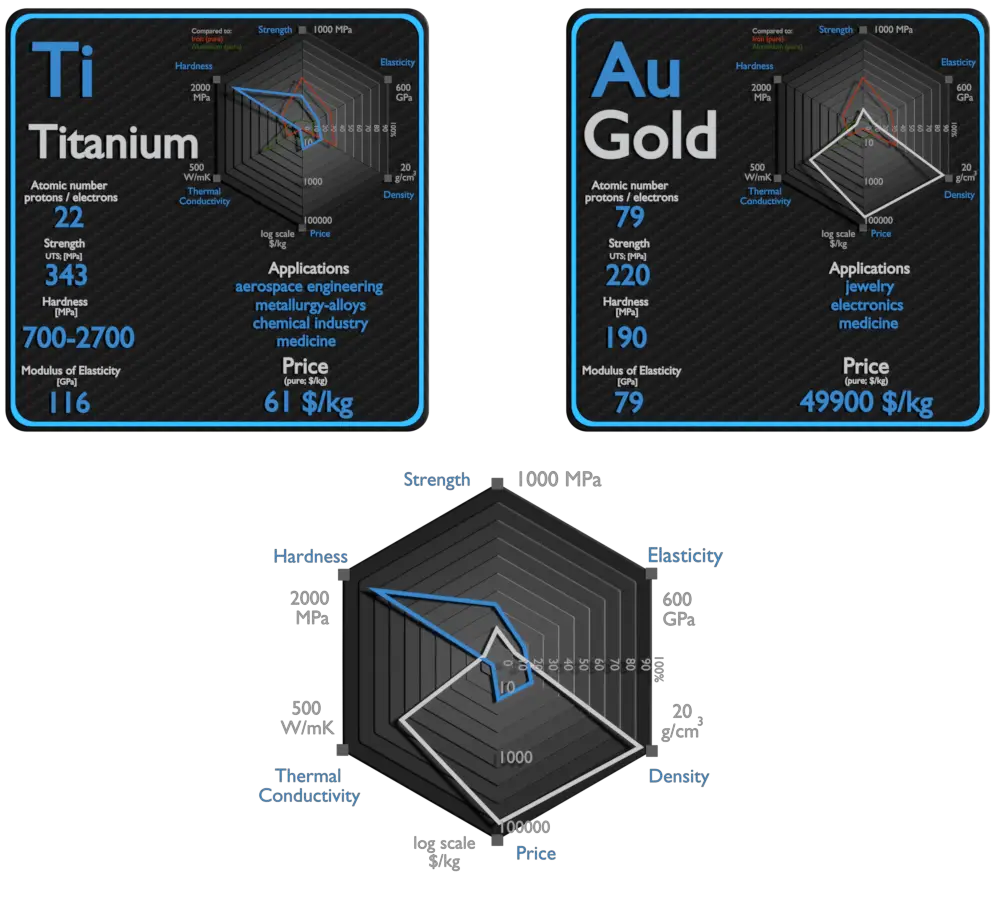

This article contains comparison of key thermal and atomic properties of titanium and gold, two comparable chemical elements from the periodic table. It also contains basic descriptions and applications of both elements. Titanium vs Gold.

Titanium and Gold – About Elements

Source: www.luciteria.com

Titanium and Gold – Applications

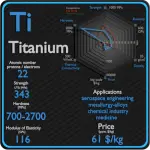

Titanium

The two most useful properties of the metal are corrosion resistance and strength-to-density ratio, the highest of any metallic element. The corrosion resistance of titanium alloys at normal temperatures is unusually high. These properties determine application of titanium and its alloys. The earliest production application of titanium was in 1952, for the nacelles and firewalls of the Douglas DC-7 airliner. High specific strength, good fatigue resistance and creep life, and good fracture toughness are characteristics that make titanium a preferred metal for aerospace applications. Aerospace applications, including use in both structural (airframe) components and jet engines, still account for the largest share of titanium alloy use. On the supersonic aircraft SR-71, titanium was used for 85% of the structure. Due to very high inertness, titanium has many biomedical applications, which is based on its inertness in the human body, that is, resistance to corrosion by body fluids.

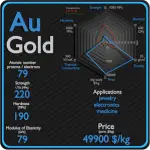

Gold

Gold is used extensively in jewellery, either in its pure form or as an alloy. About 75% of all gold produced is used in the jewelry industry. Pure gold is too soft to stand up to the stresses applied to many jewelry items. Craftsmen learned that alloying gold with other metals such as copper, silver, and platinum would increase its durability. The term ‘carat’ indicates the amount of gold present in an alloy. 24-carat is pure gold, but it is very soft. 18- and 9-carat gold alloys are commonly used because they are more durable. Gold’s high malleability, ductility, resistance to corrosion and most other chemical reactions, and conductivity of electricity have led to its continued use in corrosion resistant electrical connectors in all types of computerized devices (its chief industrial use). Gold is also used in infrared shielding, colored-glass production, gold leafing, and tooth restoration. Only 10% of the world consumption of new gold produced goes to industry, but by far the most important industrial use for new gold is in fabrication of corrosion-free electrical connectors in computers and other electrical devices.

Titanium and Gold – Comparison in Table

| Element | Titanium | Gold |

| Density | 4.507 g/cm3 | 19.3 g/cm3 |

| Ultimate Tensile Strength | 434 MPa, 293 MPa (pure) | 220 MPa |

| Yield Strength | 380 MPa | 205 MPa |

| Young’s Modulus of Elasticity | 116 GPa | 79 GPa |

| Mohs Scale | 6 | 2.75 |

| Brinell Hardness | 700 – 2700 MPa | 190 MPa |

| Vickers Hardness | 800 – 3400 MPa | 215 MPa |

| Melting Point | 1668 °C | 1064 °C |

| Boiling Point | 3287 °C | 2970 °C |

| Thermal Conductivity | 21.9 W/mK | 320 W/mK |

| Thermal Expansion Coefficient | 8.6 µm/mK | 14.2 µm/mK |

| Specific Heat | 0.52 J/g K | 0.128 J/g K |

| Heat of Fusion | 15.45 kJ/mol | 12.55 kJ/mol |

| Heat of Vaporization | 421 kJ/mol | 334.4 kJ/mol |