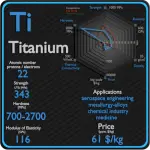

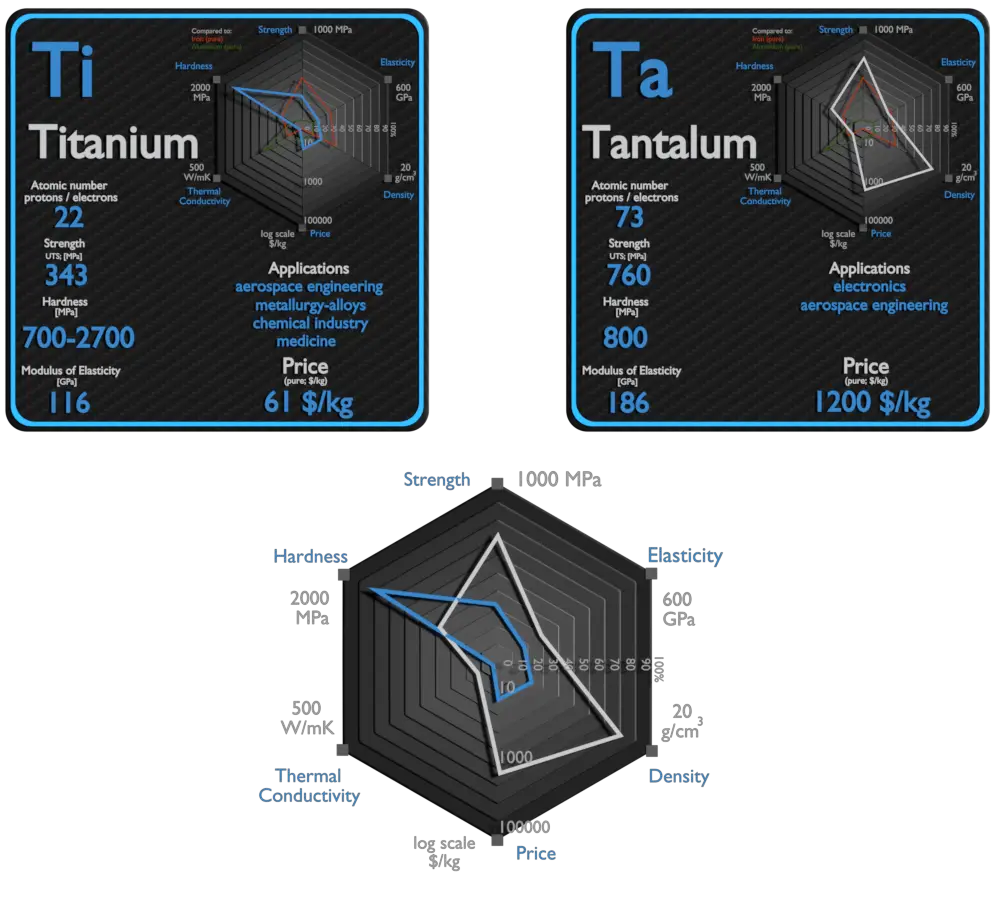

This article contains comparison of key thermal and atomic properties of titanium and tantalum, two comparable chemical elements from the periodic table. It also contains basic descriptions and applications of both elements. Titanium vs Tantalum.

Titanium and Tantalum – About Elements

Source: www.luciteria.com

Titanium and Tantalum – Applications

Titanium

The two most useful properties of the metal are corrosion resistance and strength-to-density ratio, the highest of any metallic element. The corrosion resistance of titanium alloys at normal temperatures is unusually high. These properties determine application of titanium and its alloys. The earliest production application of titanium was in 1952, for the nacelles and firewalls of the Douglas DC-7 airliner. High specific strength, good fatigue resistance and creep life, and good fracture toughness are characteristics that make titanium a preferred metal for aerospace applications. Aerospace applications, including use in both structural (airframe) components and jet engines, still account for the largest share of titanium alloy use. On the supersonic aircraft SR-71, titanium was used for 85% of the structure. Due to very high inertness, titanium has many biomedical applications, which is based on its inertness in the human body, that is, resistance to corrosion by body fluids.

Tantalum

Tantalum consumption is dominated by capacitors for electronic equipment. Capacitors are electrical components that store energy electrostatically in an electric field, and are used in a wide variety of electric and electronic products. Major end uses for tantalum capacitors include portable telephones, pagers, personal computers, and automotive electronics. Alloyed with other metals, tantalum is also used in making carbide tools for metalworking equipment and in the production of superalloys for jet engine components. Compounds of tantalum such as tantalum pentoxide is used to make capacitors and glass with a high index of refraction for use in camera lenses.

Titanium and Tantalum – Comparison in Table

| Element | Titanium | Tantalum |

| Density | 4.507 g/cm3 | 16.65 g/cm3 |

| Ultimate Tensile Strength | 434 MPa, 293 MPa (pure) | 760 MPa |

| Yield Strength | 380 MPa | 705 MPa |

| Young’s Modulus of Elasticity | 116 GPa | 186 GPa |

| Mohs Scale | 6 | 6.5 |

| Brinell Hardness | 700 – 2700 MPa | 800 MPa |

| Vickers Hardness | 800 – 3400 MPa | 870 MPa |

| Melting Point | 1668 °C | 2996 °C |

| Boiling Point | 3287 °C | 5425 °C |

| Thermal Conductivity | 21.9 W/mK | 57 W/mK |

| Thermal Expansion Coefficient | 8.6 µm/mK | 6.3 µm/mK |

| Specific Heat | 0.52 J/g K | 0.14 J/g K |

| Heat of Fusion | 15.45 kJ/mol | 31.6 kJ/mol |

| Heat of Vaporization | 421 kJ/mol | 743 kJ/mol |