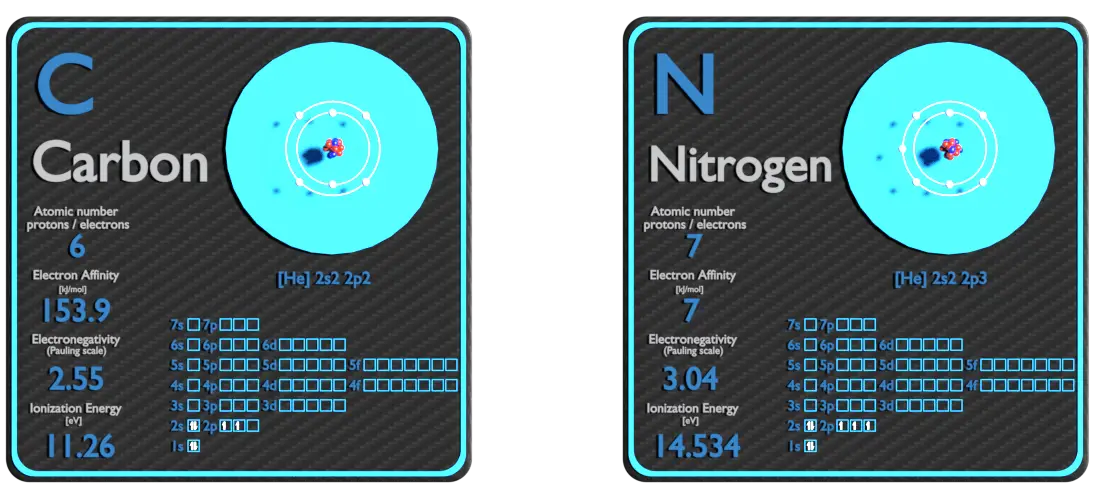

This article contains comparison of key thermal and atomic properties of carbon and nitrogen, two comparable chemical elements from the periodic table. It also contains basic descriptions and applications of both elements. Carbon vs Nitrogen.

Carbon and Nitrogen – About Elements

Source: www.luciteria.com

Carbon and Nitrogen – Applications

Carbon

The major economic use of carbon other than food and wood is in the form of hydrocarbons, most notably the fossil fuel methane gas and crude oil (petroleum). Graphite and diamonds are two important allotropes of carbon that have wide applications. The uses of carbon and its compounds are extremely varied. It can form alloys with iron, of which the most common is carbon steel. Carbon is a non-metallic element, which is an important alloying element in all ferrous metal based materials. Carbon is always present in metallic alloys, i.e. in all grades of stainless steel and heat resistant alloys. Carbon is a very strong austenitizer and increases the strength of steel. In fact, it is the principal hardening element and is essential to the formation of cementite, Fe3C, pearlite, spheroidite, and iron-carbon martensite. Adding a small amount of non-metallic carbon to iron trades its great ductility for the greater strength. Graphite is combined with clays to form the ‘lead’ used in pencils used for writing and drawing. It is also used as a lubricant and a pigment, as a molding material in glass manufacture, in electrodes for dry batteries and in electroplating and electroforming, in brushes for electric motors and as a neutron moderator in nuclear reactors. Charcoal has been used since earliest times for a large range of purposes including art and medicine, but by far its most important use has been as a metallurgical fuel. Carbon fibers are used where low weight, high stiffness, high conductivity, or where the look of the carbon fiber weave desired.

Nitrogen

Nitrogen in various chemical forms plays a major role in large number of environmental issues. The applications of nitrogen compounds are naturally extremely widely varied due to the huge size of this class: hence, only applications of pure nitrogen itself will be considered here. Two-thirds of nitrogen produced by industry is sold as the gas and the remaining one-third as the liquid. In metallurgy, nitriding is a case hardening process in which the surface nitrogen concentration of a ferrous is increased by diffusion from the surrounding environment to create case-hardened surface. Nitriding produces hard, highly wear-resistant surface (shallow case depths) of product with fair capacity for contact load, good bending fatigue strength and excellent resistance to seizure. Synthetically produced ammonia and nitrates are key industrial fertilisers, and fertiliser nitrates are key pollutants in the eutrophication of water systems. Apart from its use in fertilisers and energy-stores, nitrogen is a constituent of organic compounds as diverse as Kevlar used in high-strength fabric and cyanoacrylate used in superglue.

Carbon and Nitrogen – Comparison in Table

| Element | Carbon | Nitrogen |

| Density | 2.26 g/cm3 | 0.00125 g/cm3 |

| Ultimate Tensile Strength | 15 MPa (graphite); 3500 MPa (carbon fiber) | N/A |

| Yield Strength | N/A | N/A |

| Young’s Modulus of Elasticity | 4.1 GPa (graphite); 228 GPa (carbon fiber) | N/A |

| Mohs Scale | 0.8 (graphite) | N/A |

| Brinell Hardness | N/A | N/A |

| Vickers Hardness | N/A | N/A |

| Melting Point | 4099 °C | -209.9 °C |

| Boiling Point | 4527 °C | -195.8 °C |

| Thermal Conductivity | 129 W/mK | 0.02598 W/mK |

| Thermal Expansion Coefficient | 0.8 µm/mK | N/A |

| Specific Heat | 0.71 J/g K | 1.04 J/g K |

| Heat of Fusion | N/A | (N2) 0.7204 kJ/mol |

| Heat of Vaporization | 355.8 kJ/mol | (N2) 5.56 kJ/mol |