This article contains comparison of key thermal and atomic properties of carbon and oxygen, two comparable chemical elements from the periodic table. It also contains basic descriptions and applications of both elements. Carbon vs Oxygen.

Carbon and Oxygen – About Elements

Source: www.luciteria.com

Carbon and Oxygen – Applications

Carbon

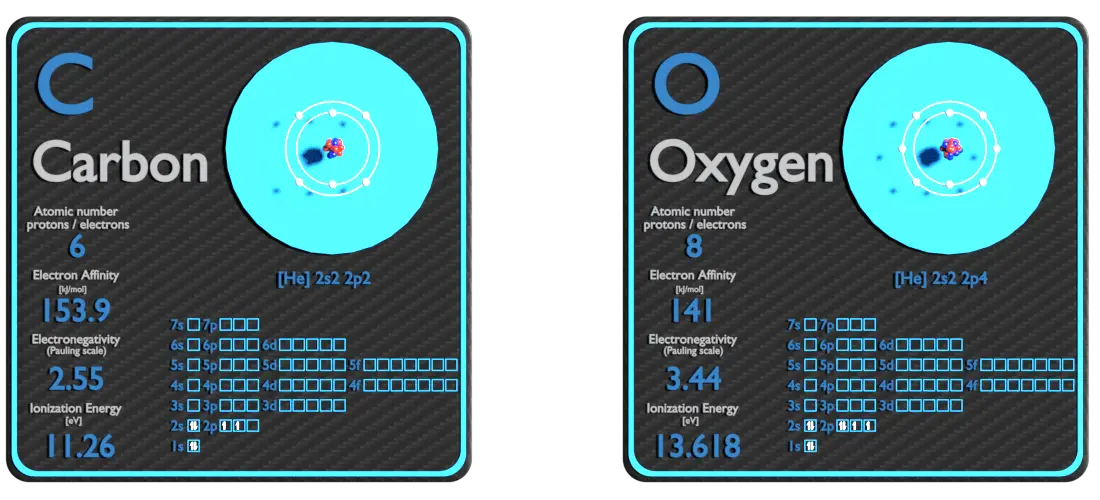

The major economic use of carbon other than food and wood is in the form of hydrocarbons, most notably the fossil fuel methane gas and crude oil (petroleum). Graphite and diamonds are two important allotropes of carbon that have wide applications. The uses of carbon and its compounds are extremely varied. It can form alloys with iron, of which the most common is carbon steel. Carbon is a non-metallic element, which is an important alloying element in all ferrous metal based materials. Carbon is always present in metallic alloys, i.e. in all grades of stainless steel and heat resistant alloys. Carbon is a very strong austenitizer and increases the strength of steel. In fact, it is the principal hardening element and is essential to the formation of cementite, Fe3C, pearlite, spheroidite, and iron-carbon martensite. Adding a small amount of non-metallic carbon to iron trades its great ductility for the greater strength. Graphite is combined with clays to form the ‘lead’ used in pencils used for writing and drawing. It is also used as a lubricant and a pigment, as a molding material in glass manufacture, in electrodes for dry batteries and in electroplating and electroforming, in brushes for electric motors and as a neutron moderator in nuclear reactors. Charcoal has been used since earliest times for a large range of purposes including art and medicine, but by far its most important use has been as a metallurgical fuel. Carbon fibers are used where low weight, high stiffness, high conductivity, or where the look of the carbon fiber weave desired.

Oxygen

Common uses of oxygen include production of steel, plastics and textiles, brazing, welding and cutting of steels and other metals, rocket propellant, oxygen therapy, and life support systems in aircraft, submarines, spaceflight and diving. Smelting of iron ore into steel consumes 55% of commercially produced oxygen. In this process, oxygen is injected through a high-pressure lance into molten iron, which removes sulfur impurities and excess carbon as the respective oxides, sulfur dioxide and carbon dioxide. Uptake of oxygen from the air is the essential purpose of respiration, so oxygen supplementation is used in medicine. Treatment not only increases oxygen levels in the patient’s blood, but has the secondary effect of decreasing resistance to blood flow in many types of diseased lungs, easing work load on the heart.

Carbon and Oxygen – Comparison in Table

| Element | Carbon | Oxygen |

| Density | 2.26 g/cm3 | 0.00143 g/cm3 |

| Ultimate Tensile Strength | 15 MPa (graphite); 3500 MPa (carbon fiber) | N/A |

| Yield Strength | N/A | N/A |

| Young’s Modulus of Elasticity | 4.1 GPa (graphite); 228 GPa (carbon fiber) | N/A |

| Mohs Scale | 0.8 (graphite) | N/A |

| Brinell Hardness | N/A | N/A |

| Vickers Hardness | N/A | N/A |

| Melting Point | 4099 °C | -218.4 °C |

| Boiling Point | 4527 °C | -183 °C |

| Thermal Conductivity | 129 W/mK | 0.02674 W/mK |

| Thermal Expansion Coefficient | 0.8 µm/mK | N/A |

| Specific Heat | 0.71 J/g K | 0.92 J/g K |

| Heat of Fusion | N/A | (O2) 0.444 kJ/mol |

| Heat of Vaporization | 355.8 kJ/mol | (O2) 6.82 kJ/mol |