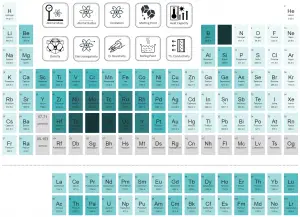

About Zinc

In some respects zinc is chemically similar to magnesium: both elements exhibit only one normal oxidation state (+2), and the Zn2+ and Mg2+ ions are of similar size.

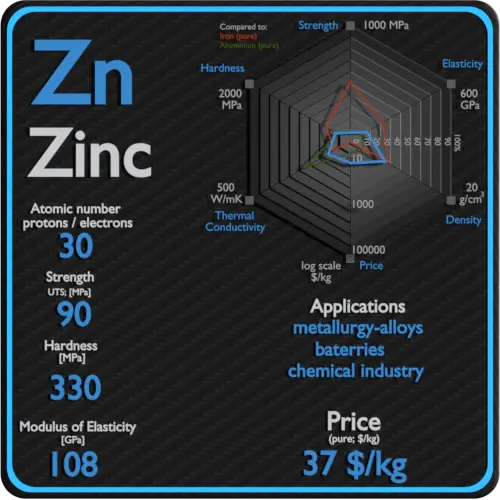

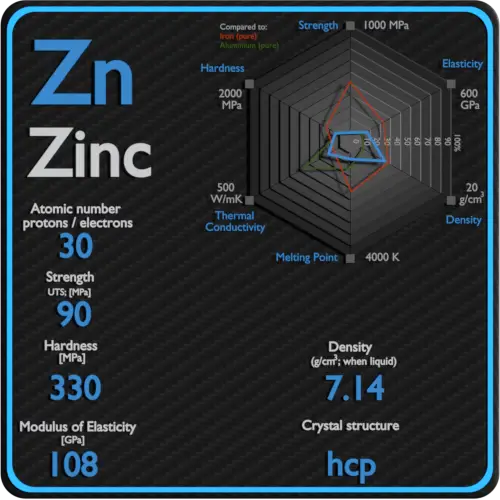

Summary

| Element | Zinc |

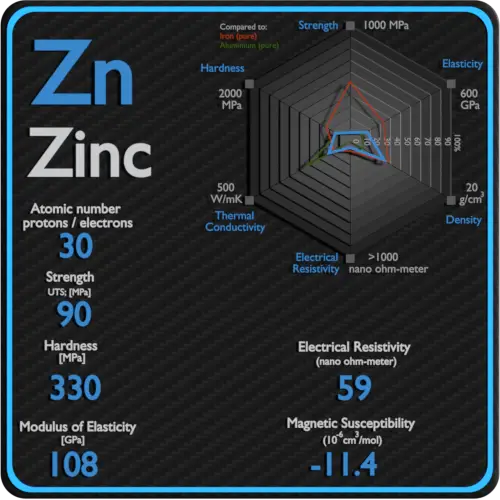

| Atomic number | 30 |

| Element category | Transition Metal |

| Phase at STP | Solid |

| Density | 7.14 g/cm3 |

| Ultimate Tensile Strength | 90 MPa |

| Yield Strength | 75 MPa |

| Young’s Modulus of Elasticity | 108 GPa |

| Mohs Scale | 2.5 |

| Brinell Hardness | 330 MPa |

| Vickers Hardness | N/A |

| Melting Point | 419.53 °C |

| Boiling Point | 907 °C |

| Thermal Conductivity | 116 W/mK |

| Thermal Expansion Coefficient | 30.2 µm/mK |

| Specific Heat | 0.39 J/g K |

| Heat of Fusion | 7.322 kJ/mol |

| Heat of Vaporization | 115.3 kJ/mol |

| Electrical resistivity [nanoOhm meter] | 59 |

| Magnetic Susceptibility | −11.4e-6 cm^3/mol |

Applications of Zinc

Corrosion-resistant zinc plating of iron (hot-dip galvanizing) is the major application for zinc. Coating of steel constitutes the largest single use of zinc, but it is used in large tonnages in zinc alloy castings, as zinc dust and oxide, and in wrought zinc products. Galvanized steel is just plain carbon steel that has been coated with a thin zinc layer. The zinc protects iron by corroding first, but zinc corrodes at much lower rates than do steel. Other applications are in electrical batteries, small non-structural castings, and alloys such as brass. A variety of zinc compounds are commonly used, such as zinc carbonate and zinc gluconate (as dietary supplements), zinc chloride (in deodorants), zinc pyrithione (anti-dandruff shampoos), zinc sulfide (in luminescent paints), and dimethylzinc or diethylzinc in the organic laboratory. A key part of the modern materials world in which zinc finds itself is recycling. Zinc, in common with all metals (and unlike synthetic materials) can be recycled indefinitely without degradation.

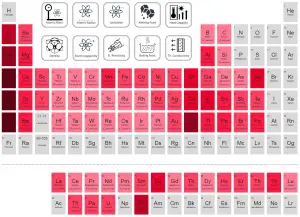

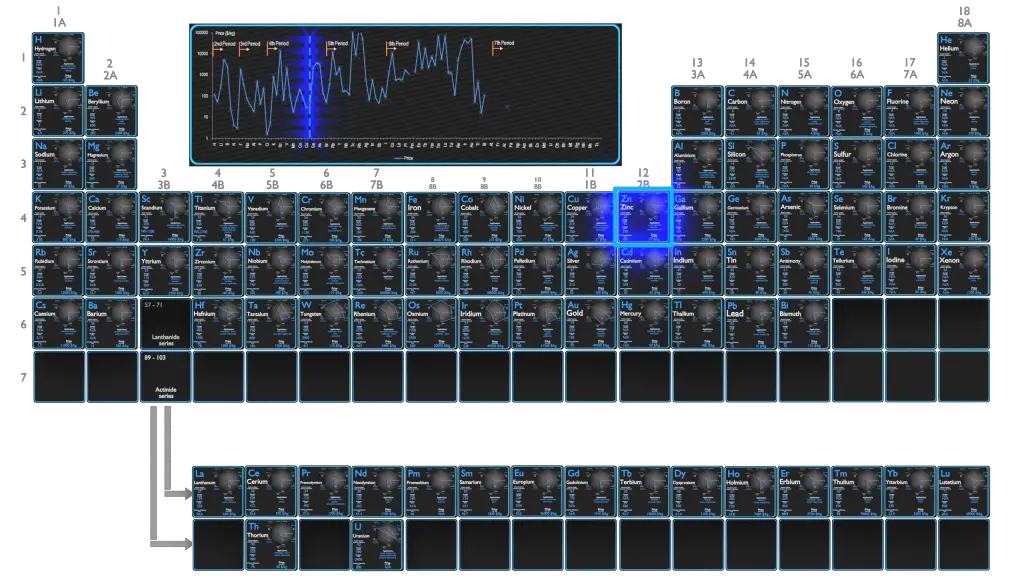

Production and Price of Zinc

Raw materials prices change daily. They are primarily driven by supply, demand and energy prices. In 2019, prices of pure Zinc were at around 37 $/kg.

The world’s largest zinc producer is Nyrstar, a merger of the Australian OZ Minerals and the Belgian Umicore. About 70% of the world’s zinc originates from mining, while the remaining 30% comes from recycling secondary zinc.

Source: www.luciteria.com

Mechanical Properties of Zinc

Strength of Zinc

In mechanics of materials, the strength of a material is its ability to withstand an applied load without failure or plastic deformation. Strength of materials basically considers the relationship between the external loads applied to a material and the resulting deformation or change in material dimensions. In designing structures and machines, it is important to consider these factors, in order that the material selected will have adequate strength to resist applied loads or forces and retain its original shape. Strength of a material is its ability to withstand this applied load without failure or plastic deformation.

For tensile stress, the capacity of a material or structure to withstand loads tending to elongate is known as ultimate tensile strength (UTS). Yield strength or yield stress is the material property defined as the stress at which a material begins to deform plastically whereas yield point is the point where nonlinear (elastic + plastic) deformation begins.

See also: Strength of Materials

Ultimate Tensile Strength of Zinc

Ultimate tensile strength of Zinc is 90 MPa.

Yield Strength of Zinc

Yield strength of Zinc is 75 MPa.

Modulus of Elasticity of Zinc

The Young’s modulus of elasticity of Zinc is 108 GPa.

Hardness of Zinc

In materials science, hardness is the ability to withstand surface indentation (localized plastic deformation) and scratching. Brinell hardness test is one of indentation hardness tests, that has been developed for hardness testing. In Brinell tests, a hard, spherical indenter is forced under a specific load into the surface of the metal to be tested.

Brinell hardness of Zinc is approximately 330 MPa.

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. The Vickers hardness test method can be also used as a microhardness test method, which is mostly used for small parts, thin sections, or case depth work.

Vickers hardness of Zinc is approximately N/A.

Scratch hardness is the measure of how resistant a sample is to permanent plastic deformation due to friction from a sharp object. The most common scale for this qualitative test is Mohs scale, which is used in mineralogy. The Mohs scale of mineral hardness is based on the ability of one natural sample of mineral to scratch another mineral visibly.

Zinc is has a hardness of approximately 2.5.

See also: Hardness of Materials

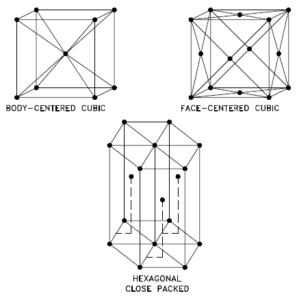

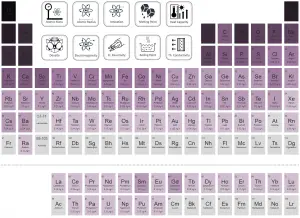

Zinc – Crystal Structure

A possible crystal structure of Zinc is hexagonal close-packed structure.

In metals, and in many other solids, the atoms are arranged in regular arrays called crystals. A crystal lattice is a repeating pattern of mathematical points that extends throughout space. The forces of chemical bonding causes this repetition. It is this repeated pattern which control properties like strength, ductility, density, conductivity (property of conducting or transmitting heat, electricity, etc.), and shape. There are 14 general types of such patterns known as Bravais lattices.

See also: Crystal Structure of Materials

Crystal Structure of Zinc

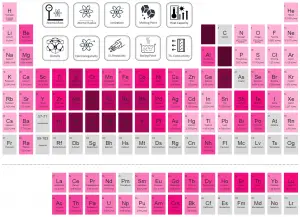

Thermal Properties of Zinc

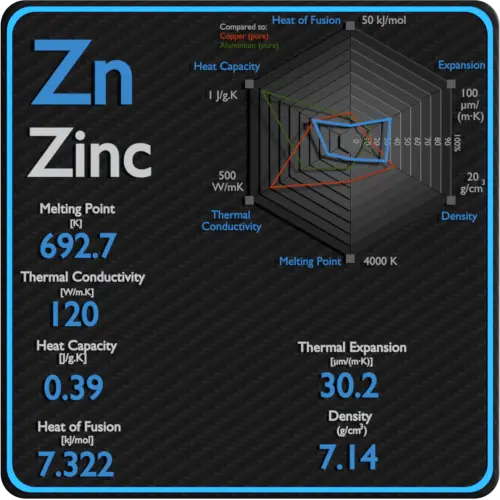

Zinc – Melting Point and Boiling Point

Melting point of Zinc is 419.53°C.

Boiling point of Zinc is 907°C.

Note that, these points are associated with the standard atmospheric pressure.

Zinc – Thermal Conductivity

Thermal conductivity of Zinc is 116 W/(m·K).

The heat transfer characteristics of a solid material are measured by a property called the thermal conductivity, k (or λ), measured in W/m.K. It is a measure of a substance’s ability to transfer heat through a material by conduction. Note that Fourier’s law applies for all matter, regardless of its state (solid, liquid, or gas), therefore, it is also defined for liquids and gases.

Coefficient of Thermal Expansion of Zinc

Linear thermal expansion coefficient of Zinc is 30.2 µm/(m·K)

Thermal expansion is generally the tendency of matter to change its dimensions in response to a change in temperature. It is usually expressed as a fractional change in length or volume per unit temperature change.

Zinc – Specific Heat, Latent Heat of Fusion, Latent Heat of Vaporization

Specific heat of Zinc is 0.39 J/g K.

Heat capacity is an extensive property of matter, meaning it is proportional to the size of the system. Heat capacity C has the unit of energy per degree or energy per kelvin. When expressing the same phenomenon as an intensive property, the heat capacity is divided by the amount of substance, mass, or volume, thus the quantity is independent of the size or extent of the sample.

Latent Heat of Fusion of Zinc is 7.322 kJ/mol.

Latent Heat of Vaporization of Zinc is 115.3 kJ/mol.

Latent heat is the amount of heat added to or removed from a substance to produce a change in phase. This energy breaks down the intermolecular attractive forces, and also must provide the energy necessary to expand the gas (the pΔV work). When latent heat is added, no temperature change occurs. The enthalpy of vaporization is a function of the pressure at which that transformation takes place.

Zinc – Electrical Resistivity – Magnetic Susceptibility

Electrical property refers to the response of a material to an applied electric field. One of the principal characteristics of materials is their ability (or lack of ability) to conduct electrical current. Indeed, materials are classified by this property, that is, they are divided into conductors, semiconductors, and nonconductors.

See also: Electrical Properties

Magnetic property refers to the response of a material to an applied magnetic field. The macroscopic magnetic properties of a material are a consequence of interactions between an external magnetic field and the magnetic dipole moments of the constituent atoms. Different materials react to the application of magnetic field differently.

See also: Magnetic Properties

Electrical Resistivity of Zinc

Electrical resistivity of Zinc is 59 nΩ⋅m.

Electrical conductivity and its converse, electrical resistivity, is a fundamental property of a material that quantifies how Zinc conducts the flow of electric current. Electrical conductivity or specific conductance is the reciprocal of electrical resistivity.

Magnetic Susceptibility of Zinc

Magnetic susceptibility of Zinc is −11.4e-6 cm^3/mol.

In electromagnetism, magnetic susceptibility is the measure of the magnetization of a substance. Magnetic susceptibility is a dimensionless proportionality factor that indicates the degree of magnetization of Zinc in response to an applied magnetic field.